Page 93 - An Introduction to Microelectromechanical Systems Engineering

P. 93

72 Processes for Micromachining

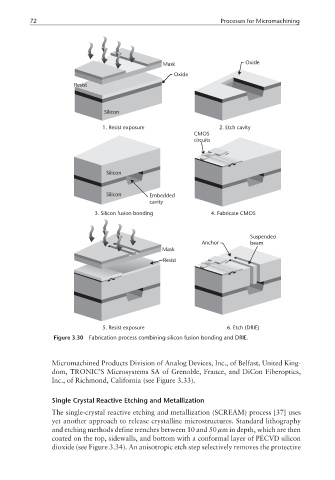

Mask Oxide

Oxide

Resist

Silicon

1. Resist exposure 2. Etch cavity

CMOS

circuits

Silicon

Silicon Embedded

cavity

3. Silicon fusion bonding 4. Fabricate CMOS

Suspended

Anchor beam

Mask

Resist

5. Resist exposure 6. Etch (DRIE)

Figure 3.30 Fabrication process combining silicon fusion bonding and DRIE.

Micromachined Products Division of Analog Devices, Inc., of Belfast, United King-

dom, TRONIC’S Microsystems SA of Grenoble, France, and DiCon Fiberoptics,

Inc., of Richmond, California (see Figure 3.33).

Single Crystal Reactive Etching and Metallization

The single-crystal reactive etching and metallization (SCREAM) process [37] uses

yet another approach to release crystalline microstructures. Standard lithography

and etching methods define trenches between 10 and 50 µm in depth, which are then

coated on the top, sidewalls, and bottom with a conformal layer of PECVD silicon

dioxide (see Figure 3.34). An anisotropic etch step selectively removes the protective