Page 94 - An Introduction to Microelectromechanical Systems Engineering

P. 94

Combining the Tools—Examples of Commercial Processes 73

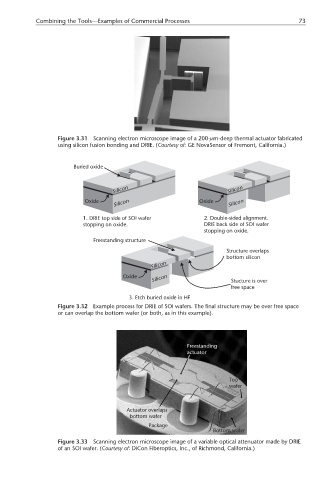

Figure 3.31 Scanning electron microscope image of a 200-µm-deep thermal actuator fabricated

using silicon fusion bonding and DRIE. (Courtesy of: GE NovaSensor of Fremont, California.)

Buried oxide

Silicon Silicon

Silicon Silicon

Oxide Oxide

1. DRIE top side of SOI wafer 2. Double-sided alignment.

stopping on oxide. DRIE back side of SOI wafer

stopping on oxide.

Freestanding structure

Structure overlaps

bottom silicon

Silicon

Oxide Silicon Stucture is over

free space

3. Etch buried oxide in HF

Figure 3.32 Example process for DRIE of SOI wafers. The final structure may be over free space

or can overlap the bottom wafer (or both, as in this example).

Freestanding

actuator

Top

wafer

Actuator overlaps

bottom wafer

Package

Bottom wafer

Figure 3.33 Scanning electron microscope image of a variable optical attenuator made by DRIE

of an SOI wafer. (Courtesy of: DiCon Fiberoptics, Inc., of Richmond, California.)