Page 299 - Analysis and Design of Machine Elements

P. 299

Shafts

gear 4, spacer 5, right rolling contact bearing 6 and bearing cover 7. The axial space 277

between bearing cover 2 and half coupling 1 is to provide access space for dismount-

ing bearing cover 2 to provide the bearing with lubricant. Figure 10.11b gives a similar

design, yet it requires a longer spacer.

10.4.6 Design Cases

Example Problem 10.1

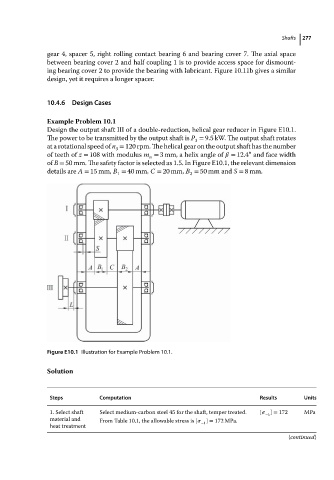

Design the output shaft III of a double-reduction, helical gear reducer in Figure E10.1.

The power to be transmitted by the output shaft is P = 9.5 kW. The output shaft rotates

3

at a rotational speed of n = 120 rpm. The helical gear on the output shaft has the number

3

∘

of teeth of z = 108 with modulus m = 3mm, a helix angle of = 12.4 and face width

n

of B = 50 mm. The safety factor is selected as 1.5. In Figure E10.1, the relevant dimension

details are A = 15 mm, B = 40 mm, C = 20 mm, B = 50 mm and S = 8 mm.

1 2

Figure E10.1 Illustration for Example Problem 10.1.

Solution

Steps Computation Results Units

1. Select shaft Select medium-carbon steel 45 for the shaft, temper treated. [ ] = 172 MPa

−1

material and From Table 10.1, the allowable stress is [ ] = 172 MPa.

−1

heat treatment

(continued)