Page 410 - Analysis and Design of Machine Elements

P. 410

Analysis and Design of Machine Elements

388

−1

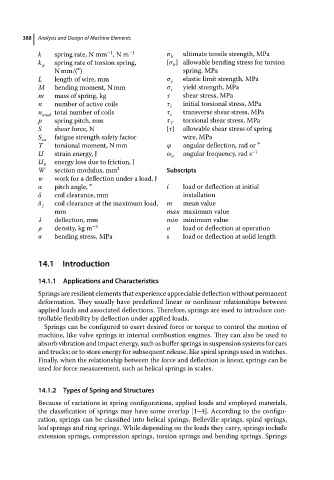

k spring rate, N mm ,Nm −1 b ultimate tensile strength, MPa

k spring rate of torsion spring, [ ] allowable bending stress for torsion

b

∘

Nmm/( ) spring, MPa

L length of wire, mm e elastic limit strength, MPa

M bending moment, N mm s yield strength, MPa

m mass of spring, kg shear stress, MPa

n number of active coils i initial torsional stress, MPa

n total total number of coils s transverse shear stress, MPa

p spring pitch, mm T torsional shear stress, MPa

S shear force, N [ ] allowable shear stress of spring

S fatigue strength safety factor wire, MPa

ca

T torsional moment, N mm angular deflection, rad or ∘

U strain energy, J angular frequency, rad s −1

n

U energy loss due to friction, J

0

W section modulus, mm 3 Subscripts

w work for a deflection under a load, J

∘

pitch angle, i load or deflection at initial

coil clearance, mm installation

1 coil clearance at the maximum load, m mean value

mm max maximum value

deflection, mm min minimum value

density, kg m −3 o load or deflection at operation

bending stress, MPa s load or deflection at solid length

14.1 Introduction

14.1.1 Applications and Characteristics

Springs are resilient elements that experience appreciable deflection without permanent

deformation. They usually have predefined linear or nonlinear relationships between

applied loads and associated deflections. Therefore, springs are used to introduce con-

trollable flexibility by deflection under applied loads.

Springs can be configured to exert desired force or torque to control the motion of

machine, like valve springs in internal combustion engines. They can also be used to

absorb vibration and impact energy, such as buffer springs in suspension systems for cars

and trucks; or to store energy for subsequent release, like spiral springs used in watches.

Finally, when the relationship between the force and deflection is linear, springs can be

used for force measurement, such as helical springs in scales.

14.1.2 Types of Spring and Structures

Because of variations in spring configurations, applied loads and employed materials,

the classification of springs may have some overlap [1–4]. According to the configu-

ration, springs can be classified into helical springs, Belleville springs, spiral springs,

leaf springs and ring springs. While depending on the loads they carry, springs include

extension springs, compression springs, torsion springs and bending springs. Springs