Page 414 - Analysis and Design of Machine Elements

P. 414

Analysis and Design of Machine Elements

392

(a) (b)

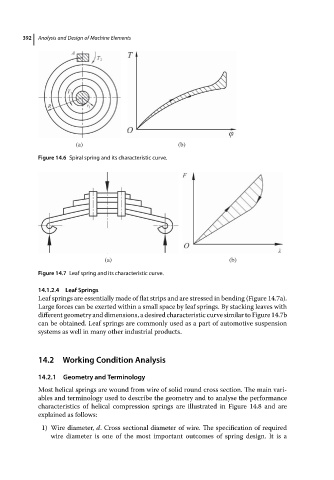

Figure 14.6 Spiral spring and its characteristic curve.

(a) (b)

Figure 14.7 Leaf spring and its characteristic curve.

14.1.2.4 Leaf Springs

Leaf springs are essentially made of flat strips and are stressed in bending (Figure 14.7a).

Large forces can be exerted within a small space by leaf springs. By stacking leaves with

different geometry and dimensions, a desired characteristic curve similar to Figure 14.7b

can be obtained. Leaf springs are commonly used as a part of automotive suspension

systems as well in many other industrial products.

14.2 Working Condition Analysis

14.2.1 Geometry and Terminology

Most helical springs are wound from wire of solid round cross section. The main vari-

ables and terminology used to describe the geometry and to analyse the performance

characteristics of helical compression springs are illustrated in Figure 14.8 and are

explained as follows:

1) Wire diameter, d. Cross sectional diameter of wire. The specification of required

wire diameter is one of the most important outcomes of spring design. It is a