Page 412 - Analysis and Design of Machine Elements

P. 412

Analysis and Design of Machine Elements

390

(a) (b) (c) (d)

Figure 14.2 Cylindrical helical compression springs with various end configurations. (a) Closed and

ground end, (b) closed end, (c) plain end and (d) plain end and ground.

changing the spacing of end coils. The plain end springs are unstable, while plain end

and ground springs in Figure 14.2d have improved stability because of partial grind-

ing of the end coils. Cylindrical helical compression springs for important applications

should be both closed and ground to ensure a better load transfer [1].

Cylindrical helical extension springs

A cylindrical helical extension spring is designed to carry tensile force and to store

energy. Extension springs appear similar to compression springs, yet they are usu-

ally closely wound, with all coils in tight contact in a free state [3]. When a sufficient

external tensile load is applied at end loops or hooks, the coils separate.

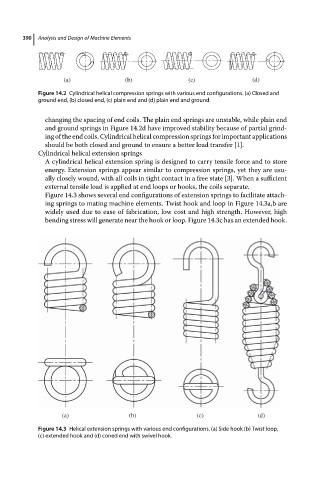

Figure 14.3 shows several end configurations of extension springs to facilitate attach-

ing springs to mating machine elements. Twist hook and loop in Figure 14.3a,b are

widely used due to ease of fabrication, low cost and high strength. However, high

bending stress will generate near the hook or loop. Figure 14.3c has an extended hook.

(a) (b) (c) (d)

Figure 14.3 Helical extension springs with various end configurations. (a) Side hook (b) Twist loop,

(c) extended hook and (d) coned end with swivel hook.