Page 330 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 330

66131_Ludwig_CH11A 5/30/2001 4:48 PM Page 289

Chapter

11

Refrigeration Systems

Process refrigeration is used at many different tempera- The most common light hydrocarbon refrigerant cooling

ture levels to condense or cool gases, vapors, or liquids. temperature ranges are (evaporation temperature):

Refrigeration is necessary when the process requires cooling

to a temperature not reliably available from the usual water Methane 200° to 300°F

service or other coolant source, including Joule-Thompson, Ethylene and ethane 75° to 175°F

or polytropic expansion of natural gas or process system Propylene and propane 40° to 50°F

vapors.

In general, auxiliary refrigeration is used for temperature Mehra 8—11 has developed a valuable series of working

requirements from 80—85°F to as near absolute zero as the charts for the common industrial refrigerants along with

process demands. The usual petrochemical and chemical application examples for ethylene, propylene, ethane, and

range does not go much below 200°F. This section does propane.

not include low-temperature air separation for oxygen,

nitrogen, argon, etc., or the separation of process gases at Terminology

liquid air temperatures.

A valuable technical presentation of refrigeration is given Ton of refrigeration: The heat equivalent to melting 2,000 lb

in the ASHRAE handbook. 2 (one ton) of ice in 24 hours. One ton equals 12,000 Btu/hr

or 200 Btu/min. To be comparative, refrigeration equip-

Types of Refrigeration Systems

ment must have the refrigerant level (or evaporation tem-

The three most used systems are as follows: perature) specified.

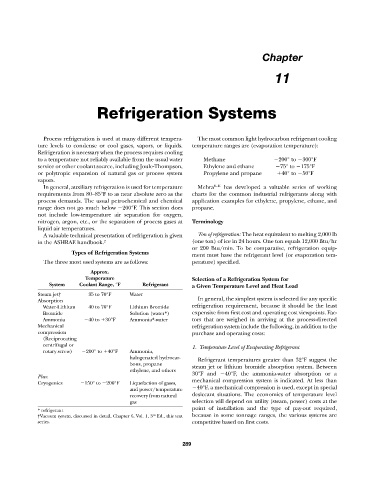

Approx.

Temperature Selection of a Refrigeration System for

System Coolant Range, °F Refrigerant a Given Temperature Level and Heat Load

Steam jet† 35 to 70°F Water

In general, the simplest system is selected for any specific

Absorption

Water-Lithium 40 to 70°F Lithium Bromide refrigeration requirement, because it should be the least

Bromide Solution (water*) expensive from first cost and operating cost viewpoints. Fac-

Ammonia 40 to 30°F Ammonia*-water tors that are weighed in arriving at the process-directed

Mechanical refrigeration system include the following, in addition to the

compression purchase and operating costs:

(Reciprocating

centrifugal or

1. Temperature Level of Evaporating Refrigerant

rotary screw) 200° to 40°F Ammonia,

halogenated hydrocar-

Refrigerant temperatures greater than 32°F suggest the

bons, propane

steam jet or lithium bromide absorption system. Between

ethylene, and others

30°F and 40°F, the ammonia-water absorption or a

Plus:

mechanical compression system is indicated. At less than

Cryogenics 150° to 200°F Liquefaction of gases,

40°F, a mechanical compression is used, except in special

and power/temperature

recovery from natural desiccant situations. The economics of temperature level

gas selection will depend on utility (steam, power) costs at the

point of installation and the type of pay-out required,

* refrigerant

†Vacuum system, discussed in detail, Chapter 6, Vol. 1, 3 Ed., this text because in some tonnage ranges, the various systems are

rd

series. competitive based on first costs.

289