Page 335 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 335

66131_Ludwig_CH11A 5/30/2001 4:49 PM Page 294

294 Applied Process Design for Chemical and Petrochemical Plants

Tons* of

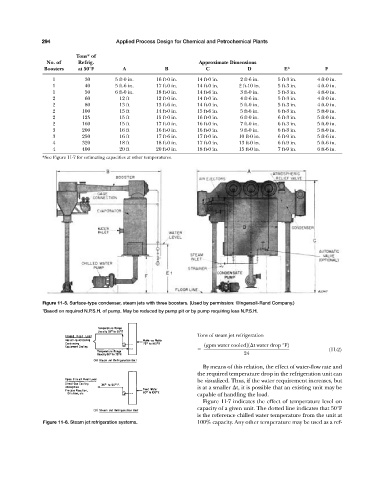

No. of Refrig. Approximate Dimensions

Boosters at 50°F A B C D E* F

1 30 5 ft-0 in. 16 ft-0 in. 14 ft-0 in. 2 ft-6 in. 5 ft-3 in. 4 ft-0 in.

1 40 5 ft-6 in. 17 ft-0 in. 14 ft-0 in. 2 ft-10 in. 5 ft-3 in. 4 ft-0 in.

1 50 6 ft-0 in. 18 ft-0 in. 14 ft-6 in. 3 ft-0 in. 5 ft-3 in. 4 ft-0 in.

2 60 12 ft 12 ft-0 in. 14 ft-0 in. 4 ft-6 in. 5 ft-3 in. 4 ft-0 in.

2 80 13 ft 13 ft-6 in. 14 ft-0 in. 5 ft-0 in. 5 ft-3 in. 4 ft-0 in.

2 100 15 ft 14 ft-0 in. 15 ft-6 in. 5 ft-6 in. 6 ft-3 in. 5 ft-0 in.

2 125 15 ft 15 ft-0 in. 16 ft-0 in. 6 ft-0 in. 6 ft-3 in. 5 ft-0 in.

2 160 15 ft 17 ft-0 in. 16 ft-0 in. 7 ft-0 in. 6 ft-3 in. 5 ft-0 in.

3 200 16 ft 16 ft-0 in. 16 ft-0 in. 9 ft-0 in. 6 ft-3 in. 5 ft-0 in.

3 250 16 ft 17 ft-6 in. 17 ft-0 in. 10 ft-0 in. 6 ft-9 in. 5 ft-6 in.

4 320 18 ft 18 ft-0 in. 17 ft-0 in. 13 ft-0 in. 6 ft-9 in. 5 ft-6 in.

4 400 20 ft 20 ft-0 in. 18 ft-0 in. 15 ft-0 in. 7 ft-9 in. 6 ft-6 in.

*See Figure 11-7 for estimating capacities at other temperatures.

† †

†

Figure 11-5. Surface-type condenser, steam jets with three boosters. (Used by permission: ©Ingersoll-Rand Company.)

† Based on required N.P.S.H. of pump. May be reduced by pump pit or by pump requiring less N.P.S.H.

Tons of steam jet refrigeration

1gpm water cooled21 t water drop °F2

(11-2)

24

By means of this relation, the effect of water-flow rate and

the required temperature drop in the refrigeration unit can

be visualized. Thus, if the water requirement increases, but

is at a smaller t, it is possible that an existing unit may be

capable of handling the load.

Figure 11-7 indicates the effect of temperature level on

capacity of a given unit. The dotted line indicates that 50°F

is the reference chilled water temperature from the unit at

Figure 11-6. Steam jet refrigeration systems. 100% capacity. Any other temperature may be used as a ref-