Page 332 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 332

66131_Ludwig_CH11A 5/30/2001 4:49 PM Page 291

Refrigeration Systems 291

7. Steam condensate can be recovered in surface type

units.

8. Refrigeration tonnage can be varied as to amount and

temperature level.

9. Start up and operation are simple.

10. Barometric units can use dirty, brackish, or waste water.

11. Cost per ton of refrigeration is relatively low.

Materials of Construction

The main fabricated parts of the units are carbon steel, with

suitable corrosion allowance for the conditions of the chilled

and condensing water. When brackish or sea water is used

1

in a barometric condenser, steel construction with a / 4 -in. to

3 / 8 -in. corrosion allowance is suggested, and minimum wall

1

3

plates of / 2 -in. to / 4 -in. may be justified. Internal splash

1

3

plates should be / 2 -in. to / 4 -in. minimum, because the

atmosphere of water vapor-air is very corrosive. Alloy con-

struction is not justified except in exceptional cases.

For surface condensers, the tubes, tubesheets, and shell

should be consistent with experiences in heat exchanger

construction. In sea or brackish water, one of the cupro-

nickels or aluminum brass may be a good choice for tubes.

The water boxes may be vertically divided to allow half of

the unit to operate while the other half is being opened for

repair or inspection.

The booster ejectors are usually of steel plate (or cast)

with Monel steam nozzles.

The air ejectors are usually of cast iron with Monel noz-

zles. The associated inter- and after-condensers are usually of

cast iron shell and water boxes with Admiralty tubes (unless

sea or brackish water) with Muntz metal tubesheets. Some

inter- and after-condensers may also be barometric rather

than tubular.

These units usually come complete with interconnecting

piping, valves, strainers, control valves, level controls, gages,

water pumps, etc. The specifications should state how much

of this is desired by the purchaser, as well as delineating each

detail peculiar to the system, such as the use of sea or brack-

ish water, special materials of construction for condenser

water, steam, chilled water, etc.

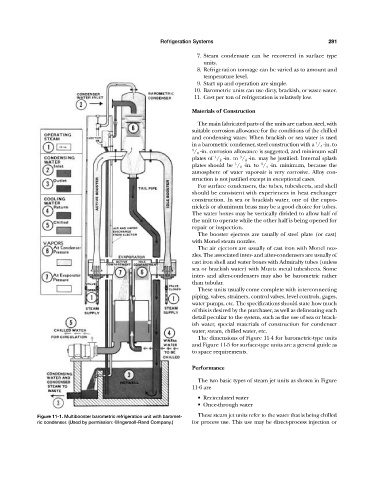

The dimensions of Figure 11-4 for barometric-type units

and Figure 11-5 for surface-type units are a general guide as

to space requirements.

Performance

The two basic types of steam jet units as shown in Figure

11-6 are

• Recirculated water

• Once-through water

Figure 11-1. Multibooster barometric refrigeration unit with baromet- These steam jet units refer to the water that is being chilled

ric condenser. (Used by permission: ©Ingersoll-Rand Company.) for process use. This use may be direct-process injection or