Page 334 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 334

66131_Ludwig_CH11A 5/30/2001 4:49 PM Page 293

Refrigeration Systems 293

indirect for heat exchangers or similar equipment. Water for

a once-through system need only be as free from impurities as

its use and reasonable corrosion conditions require; whereas

the recirculated water is usually condensate (with condensate

make-up) with blow-down or treatment to avoid solids or

other contaminant build up. The principles of design and

selection are the same for the two types.

Capacity

Heat load of process per hr

Tons of refrigeration required

12,000 Btu>hr.

(11-1)

†

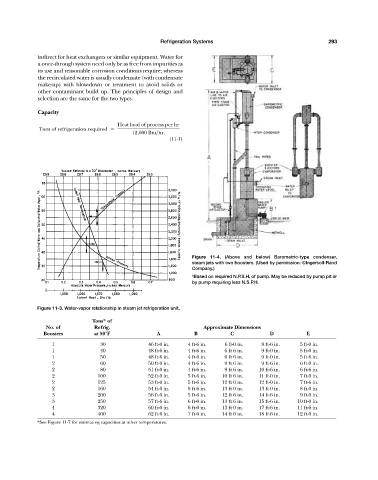

Figure 11-4. (Above and below) Barometric-type condenser,

steam jets with two boosters. (Used by permission: ©Ingersoll-Rand

Company.)

† Based on required N.P.S.H. of pump. May be reduced by pump pit or

by pump requiring less N.S.P.H.

Figure 11-3. Water-vapor relationship in steam jet refrigeration unit.

Tons* of

No. of Refrig. Approximate Dimensions

Boosters at 50°F A B C D E

1 30 46 ft-0 in. 4 ft-6 in. 6 ft-0 in. 8 ft-6 in. 5 ft-0 in.

1 40 48 ft-6 in. 4 ft-6 in. 6 ft 6 in. 9 ft-0 in. 5 ft-0 in.

1 50 48 ft-6 in. 4 ft-6 in. 6 ft 6 in. 9 ft-0 in. 5 ft-6 in.

2 60 50 ft-0 in. 4 ft-6 in. 9 ft 6 in. 9 ft-6 in. 6 ft-0 in.

2 80 51 ft-0 in. 4 ft-6 in. 9 ft 6 in. 10 ft-6 in. 6 ft-6 in.

2 100 52 ft-0 in. 5 ft-6 in. 10 ft 6 in. 11 ft-0 in. 7 ft-0 in.

2 125 53 ft-0 in. 5 ft-6 in. 12 ft 0 in. 12 ft-0 in. 7 ft-6 in.

2 160 54 ft-0 in. 5 ft-6 in. 13 ft 0 in. 13 ft-0 in. 8 ft-0 in.

3 200 56 ft-0 in. 5 ft-6 in. 12 ft 6 in. 14 ft-6 in. 9 ft-0 in.

3 250 57 ft-6 in. 6 ft-0 in. 13 ft 6 in. 15 ft-6 in. 10 ft-0 in.

4 320 60 ft-0 in. 6 ft-0 in. 13 ft 0 in. 17 ft-6 in. 11 ft-6 in.

4 400 62 ft-6 in. 7 ft-0 in. 14 ft 0 in. 18 ft-6 in. 12 ft-0 in.

*See Figure 11-7 for estimating capacities at other temperatures.