Page 349 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 349

66131_Ludwig_CH11A 5/30/2001 4:49 PM Page 306

306 Applied Process Design for Chemical and Petrochemical Plants

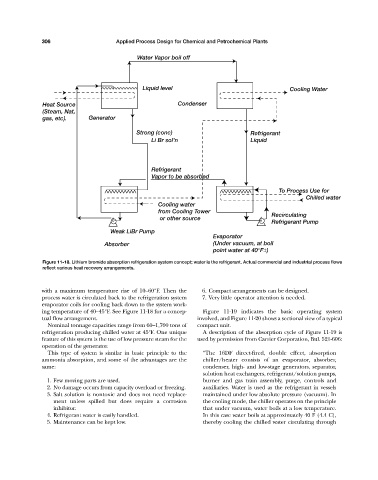

Water Vapor boil off

Liquid level Cooling Water

Heat Source Condenser

(Steam, Nat,

gas, etc). Generator

Strong (conc) Refrigerant

Li Br sol'n Liquid

Refrigerant

Vapor to be absorbed

To Process Use for

Chilled water

Cooling water

from Cooling Tower

Recirculating

or other source

Refrigerant Pump

Weak LiBr Pump

Evaporator

Absorber (Under vacuum, at boil

point water at 40°F±)

Figure 11-18. Lithium bromide absorption refrigeration system concept; water is the refrigerant. Actual commercial and industrial process flows

reflect various heat recovery arrangements.

with a maximum temperature rise of 10—60°F. Then the 6. Compact arrangements can be designed.

process water is circulated back to the refrigeration system 7. Very little operator attention is needed.

evaporator coils for cooling back down to the system work-

ing temperature of 40—45°F. See Figure 11-18 for a concep- Figure 11-19 indicates the basic operating system

tual flow arrangement. involved, and Figure 11-20 shows a sectional view of a typical

Nominal tonnage capacities range from 60—1,700 tons of compact unit.

refrigeration producing chilled water at 45°F. One unique A description of the absorption cycle of Figure 11-19 is

feature of this system is the use of low pressure steam for the used by permission from Carrier Corporation, Bul. 521-606:

operation of the generator.

This type of system is similar in basic principle to the “The 16DF direct-fired, double effect, absorption

ammonia absorption, and some of the advantages are the chiller/heater consists of an evaporator, absorber,

same: condenser, high- and low-stage generators, separator,

solution heat exchangers, refrigerant/solution pumps,

1. Few moving parts are used. burner and gas train assembly, purge, controls and

2. No damage occurs from capacity overload or freezing. auxiliaries. Water is used as the refrigerant in vessels

3. Salt solution is nontoxic and does not need replace- maintained under low absolute pressure (vacuum). In

ment unless spilled but does require a corrosion the cooling mode, the chiller operates on the principle

inhibitor. that under vacuum, water boils at a low temperature.

4. Refrigerant water is easily handled. In this case water boils at approximately 40 F (4.4 C),

5. Maintenance can be kept low. thereby cooling the chilled water circulating through