Page 401 - Applied Process Design For Chemical And Petrochemical Plants Volume III

P. 401

66131_Ludwig_CH11A 5/30/2001 4:50 PM Page 358

358 Applied Process Design for Chemical and Petrochemical Plants

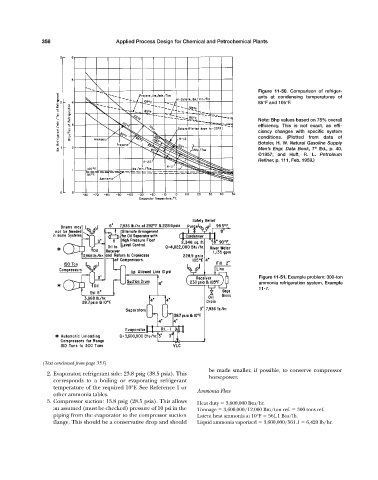

Figure 11-50. Comparison of refriger-

ants at condensing temperatures of

85°F and 105°F.

Note: Bhp values based on 75% overall

efficiency. This is not exact, as effi-

ciency changes with specific system

conditions. (Plotted from data of

Boteler, H. W. Natural Gasoline Supply

Men’s Engr. Data Book, 7 Ed., p. 40,

th

©1957; and Huff, R. L. Petroleum

Refiner, p. 111, Feb. 1959.)

Figure 11-51. Example problem: 300-ton

ammonia refrigeration system, Example

11-7.

(Text continued from page 353)

be made smaller, if possible, to conserve compressor

2. Evaporator, refrigerant side: 23.8 psig (38.5 psia). This

horsepower.

corresponds to a boiling or evaporating refrigerant

temperature of the required 10°F. See Reference 1 or

Ammonia Flow

other ammonia tables.

3. Compressor suction: 13.8 psig (28.5 psia). This allows Heat duty 3,600,000 Btu/hr.

an assumed (must be checked) pressure of 10 psi in the Tonnage 3,600,000/12,000 Btu/ton ref. 300 tons ref.

piping from the evaporator to the compressor suction Latent heat ammonia at 10°F 561.1 Btu/lb.

flange. This should be a conservative drop and should Liquid ammonia vaporized 3,600,000/561.1 6,420 lb/hr.