Page 82 - Applied Photovoltaics

P. 82

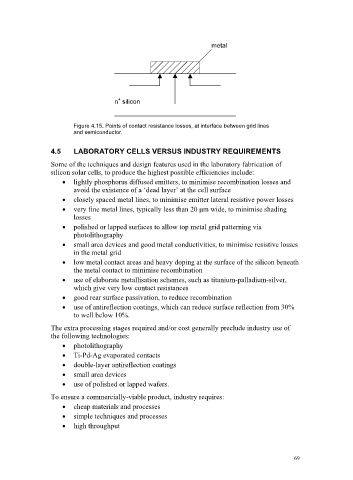

metal

+

n silicon

Figure 4.15. Points of contact resistance losses, at interface between grid lines

and semiconductor.

4.5 LABORATORY CELLS VERSUS INDUSTRY REQUIREMENTS

Some of the techniques and design features used in the laboratory fabrication of

silicon solar cells, to produce the highest possible efficiencies include:

x lightly phosphorus diffused emitters, to minimise recombination losses and

avoid the existence of a ‘dead layer’ at the cell surface

x closely spaced metal lines, to minimise emitter lateral resistive power losses

x very fine metal lines, typically less than 20 ȝm wide, to minimise shading

losses

x polished or lapped surfaces to allow top metal grid patterning via

photolithography

x small area devices and good metal conductivities, to minimise resistive losses

in the metal grid

x low metal contact areas and heavy doping at the surface of the silicon beneath

the metal contact to minimise recombination

x use of elaborate metallisation schemes, such as titanium-palladium-silver,

which give very low contact resistances

x good rear surface passivation, to reduce recombination

x use of antireflection coatings, which can reduce surface reflection from 30%

to well below 10%.

The extra processing stages required and/or cost generally preclude industry use of

the following technologies:

x photolithography

x Ti-Pd-Ag evaporated contacts

x double-layer antireflection coatings

x small area devices

x use of polished or lapped wafers.

To ensure a commercially-viable product, industry requires:

x cheap materials and processes

x simple techniques and processes

x high throughput

69