Page 126 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 126

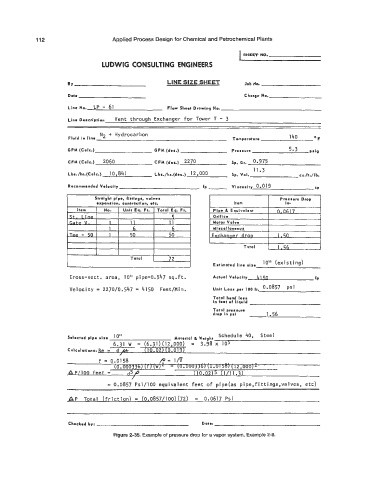

112 Applied Process Design for Chemical and Petrochemical Plants

snEEr NO.

LUDWIG CONSULTING ENGINEERS

BY LINE SIZE SHEET Job 210.

Date Charge No.

Line No. Lp - 61 Flow Sheet Drowi>ng No.

Vent through Exchanger for Tower T - 3

LineDescription

Np + Hydrocarbon

Fluid in line Temperature 140 OF

prig

GPM (Calc.) 2060 GPM (des.) 2270 Pressure 11.3 5.3 cu.ft./lb.

Sp. Gr. O.975

*

CFM (des.)

CFM (COIC.)

10,841

12,000

sp. Val.

Lbs./hr.(Colc.)

Lbs./hr.(des.)

Viscosity 0.019

Recommended Velocity

CP

fP ~

Total Eq. Ft.

No.

Unit Eq. Ft.

Item

5

St. 1 ine

I

I

1.56

Total

Total

Estimated line size Iott (existing)

Cross-sect. area, 10" pipe=O.547 sq.ft. Actual Velocity 41 r;n fp

Velocity = 2270/0.547 = 4150 Feet/Min. Unit ~ors per 100 ft. 0.0857 psi

Total head loss

in feet of liquid

Total pressure

drop in psi 1.56

Selected pipe size lo" Material L Weight Schedule 40, Steel

6.31 w = (6.31)(12,OOO) = 3.98 x 105

Colculatians:& $

=

1

f = 0.0158 e= 1/0 CL

(0.000336) (fJ (WJ' - - UUUjjb, (U.m [ IZ,000JL. .

.AP/IOO feet = (10.02)5 (1/11.3)

-

= 0.0857 Psi/lOO equivalent feet of pipe(as pipe,fittings,valves, etc)

,AP Total (friction) = (0.0857/100)(72) = 0.0617 Psi

~

Checked by: Date:

Figure 2-35. Example of pressure drop for a vapor system, Example 2-8.