Page 151 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 151

Fluid Flow 137

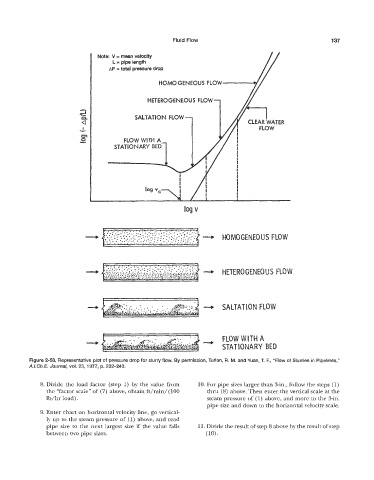

Note: V = mean velocity

L = pipe length

AP = total pressure drop

HOMOGENEOUS FLOW

HETEROGENEOUS FLOW

SALTATION FLOW

FLOW WITH A

STATIONARY BE

---* HOMOGENEOUS F

e. .... ...... ... ......_...

_3 : :....:, .:.....: : : ..,.. - HETEROGENEOUS F

4 - SALTATION FLOW

+ FLOW WITH A

STATIONARY BE

Figure 2-50. Representative plot of pressure drop for slurry flow. By permission, Turian, R. M. and Yuan, T. F., “Flow of Slurries in Pipelines,”

A.1.Ch.E. Journal, VQI. 23, 1 977, p. 232-24.3.

8. Divide the load factor (step 1) by the value from 10. For pipe sizes larger than 3h., follow the steps (1)

the “factor sca.le” of (7) above, obtain ft/min/ (100 thru (8) above. Then enter the vertical scale at the

Ib/hr load). steam pressure of (1) above, and more to the 3-in.

pipe size and down to the horizontal velocity scale.

9. Enter chart 011 horizontal velocity line, go vertical-

ly up to the steam pressure of (1) above, and read

pipe size to the next largest size if the value falls 11. Divide the result of step 8 above by the result of step

between two pipe sizes. (10).