Page 204 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 204

Pumping of Liquids 177

- Barrier Fluid In head is twice that of the rated pressure of one pump at the

roduct Y------7 designated flow rate (Figure 3-35). The pump casing of

each stage (particularly the last) must be of sufficient pres-

sure rating to withstand the developed pressure.

Pumps in Pardel

Figure 3-31C. Double mechanical seal, two rotary elements against

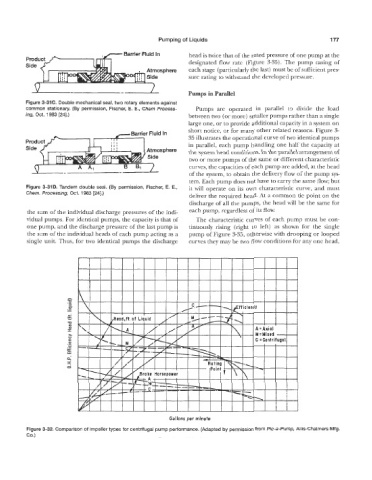

c0mm0n stationary. (By permission, Fischer, E. E., Chern Process- Pumps are operated in parallel to divide the load

ing, Oct. 1983 [24]1.) between two (or more) smaller pumps rather than a single

large one, or to provide additional capacity in a system on

short notice, or for many other related reasons. Figure 3-

r Fluid In

35 illustrates the operational curve of two identical pumps

Product in parallel, each pump handling one half the capacity at

sphere the system head conditions. In the parallel arrangement of

two or more pumps of the same or different characteristic

curves, the capacities of each pump are added, at the head

of the system, to obtain the delivery BOW of the pump sys-

tem. Each pump does not have to carry the same flow; but

. Tandem double seal. (By permission, Fischer, E. E., it will operate on its own characteristic curve, and must

Chem. Processing, Oct. 1983 [24].) deliver the required head. At a common tie point on the

discharge of all the pumps, the head will be the same for

the sum of the individual discharge pressures of the indi- each pump, regardless of its flow.

vidual pumps. For identical pumps, the capacity is that of The characteristic curves of each pump must be con-

one pump, and the discharge pressure of the last pump is tinuously rising (right to left) as shown for the single

the sum of the individual heads of each pump acting as a pump of Figure 3-35, otherwise with drooping or looped

single unit. Thus, for two identical pumps the discharge curves they may be two flow conditions for any one head,

Gallons per minute

2. Comparison of impeller types for centrifugal pump performance. (Adapted by permission from Pic-a-Pump, Allis-Chalmers Mfg.

GO.)