Page 201 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 201

174 Applied Process Design for Chemical and Petrochemical Plants

2 N.P.T's for Circulating

/Lubrication I

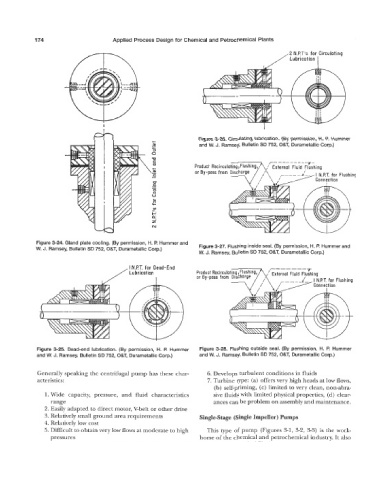

Figure 3-26. Circulating lubrication. (By permission, H. P. Hummer

and W. J. Ramsey, Bulletin SD 752, O&T3 Durametallic Corp.)

r- --- -- - -- 7-

I

or By-pass from Discharge

Figure 3-24. Gland plate cooling. (By permission, H. P. Hummer and Figure 3-27. Flushing inside seal. (By permission, H. P. Hummer and

W. J. Ramsey, Bulletin SD 752, O&T, Durametallic Corp.)

W. J. Ramsey, Bulletin SD 752, O&T, Durametallic Corp.)

I NIT, for Dead-End I-------

/ Lubrication Product Recirculat

Figure 3-25. Dead-end lubrication. (By permission, H. P. Hummer Figure 3-28. Flushing outside seal. (By permission, H. P. Hummer

and W. J. Ramsey. Bulletin SD 752, O&T, Durametallic Corp.) and W. J. Ramsey, Bulletin SD 752, O&T, Durametallic Corp.)

Generally speaking the centrifugal pump has these char- 6. Develops turbulent conditions in fluids

acteristics: 7. Turbine type: (a) offers very high heads at low flows,

(b) self-priming, (c) limited to very clean, non-abra-

1. Wide capacity, pressure, and fluid characteristics sive fluids with limited physical properties, (d) clear-

range ances can be problem on assembly and maintenance.

2. Easily adapted to direct motor, V-belt or other drive

3. Relatively small ground area requirements Single-Stage (Single Impeller) Pumps

4. Relatively low cost

5. Difficult to obtain very low flows at moderate to high This type of pump (Figures 3-1, 3-2, 3-3) is the work-

pressures horse of the chemical and petrochemical industry. It also