Page 198 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 198

Pumping of Liquids 171

Turn Pump Over by Hand before Starting No.

- Part Name

Motor to see that It Turns Freely.

I. Pump Casing

.xay 3. Impeller

Lubricate Stuffina Box 4. Pump Frame

BY Circulating Waier or 7. Split Gland

Clear Solution thr; ~ IO. Shaft

Connections “x” a Y . 12. Lontern Ring

13. Packing

44. Nipple (2)

Tang 55. Thrower Ring

Must be 56. Rubber Ring

5 9.

~ .. Resilient Sleeve

60. Shaft Sleeve

61. Rubber Ring

^^

Retaining Ring

Rubber Ring

Capscrew (6)

Gland Yoke

Key

Shaft Sleeve Ext’n.

Impeller Tie Rod

Key

Lining 164. Washer (2)

165. Retainer (2)

167. Rubber Ring (2)

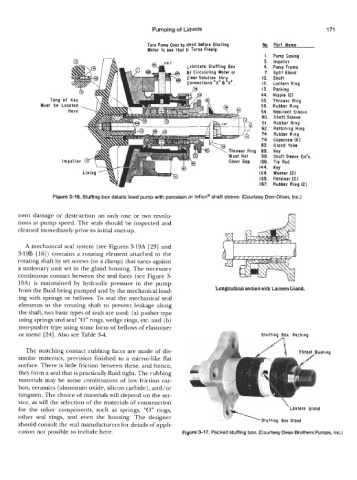

Figure 3-16. Stuffing box details lined pump with porcelain or teflon@ shaft sleeve. (Courtesy Dorr-Oliver, Inc.)

nent damage or destruction on only one or two revolu-

tions at pump speed. The seals should be inspected and

cleaned immediately prior to initial start-up.

A mechanical seal system (see Figures 3-19A [23] and

3-19B [16]) contains a rotating element attached to the

rotating shaft by set screws (or a clamp) that turns against

a stationary unit set in the gland housing. The necessary

continuous contact between the seal faces (see Figure 3-

19A) is maintained by hydraulic pressure in the pump ba

from the fluid being pumped and by the mechanical load- Longitudinal sectionwith Lantern Gland.

ing with springs or bellows. To seal the mechanical seal

elements to the rotating shaft to prevent leakage along

the shaft, two basic types of seals are used: (a) pusher type

using springs and seal “0” rings, wedge rings, etc. and (b)

non-pusher type using some form of bellows of elastomer

or metal [24]. Also see Table 3-4.

The matching contact rubbing faces are made of dis-

similar materials, precision finished to a mirror-like flat

surface. There is little friction between these, and hence,

they form a seal that is practically fluid tight. The rubbing

materials may be some combination of low friction car-

bon, ceramics (aluminum oxide, silicon carbide), and/or

tungsten. The choice of materials will depend on the ser-

vice, as will the selection of the materials of construction

for the other components, such as springs, “0” rings, ‘Lantern Gland

other seal rings, and even the housing. The designer

should consult the seal manufacturers for details of appli- Stuffing Box Gland

cation not possible to include here. Figure 3-17. Packed stuffing box. (Courtesy Dean Brothers Pumps, Inc.)