Page 193 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 193

166 Applied Process Design for Chemical and Petrochemical Plants

Table 3-3 ance between these two faces prevents leak-

Basic Parts of a Centrifugal Pump age of liquid out or air in.

Shaft sleeve Protects the shaft where it passes through the

Part Purpose stuffing box. Usually used in pumps with

Impeller Imparts velocity to the liquid, resulting from packing but often eliminated if mechanical

centrifugal force as the impeller is rotated. seals are employed.

Casing Gives direction to the flow from the impeller Wearing rings Keeps internal recirculation down to a mini-

and converts this velocity energy into pres- mum. Having these rings as replaceable wear-

sure energy which is usually measured in feet ing surfaces permits renewal of clearances to

of head. keep pump efficiencies high. On mall types

only one ring is used in the casing and on

Shaft Transmits power from the driver to the im- larger sizes, companion rings are used in the

peller. casing and on the impeller.

Stuffing box This is a means of throttling the leakage

which would otherwise oc~w at the point of Wearing plates With open type impellers or end clearance

entry of the shaft into the casing. Usually not wearing fits, these perform the same purpose

a separate part, but rather made up of a as wearing rings do with radial clearances.

group of small details, as “A” to “D”. Bearings Accurately locate shaft and carry radial and

(A) Packing This is the most common means of throttling thrust loads.

the leakage between the inside and outside of

the casing. Frame To mount unit rigidly and support bearings.

(B) Gland To position and adjust the packing pressure. In most single suction pumps this is a sepa-

(C) Seal gage Provides passage to distribute the sealing me- rate piece. In many double suction pumps, the

(also called dium uniformly around the portion of the support is through feet cast as part of the

water-seal shaft that passes through the stuffing box. casing. In some special suction pumps, the

OF lantern This is very essential when suction lift con- feet are also part of the casing and the bear-

ring ditions prevail to seal against in-leakage of air. ing assembly is overhung. With close coupled

single suction types, this support is provided

(D) Mechanical Provides a mechanical sealing arrangement by the motor or by special supporting adap-

seal that takes the place of the packing. Basically ters.

it has one surface rotating with the shaft and

one stationary face. The minutely close clear- Coupling Connects the pump to the driver.

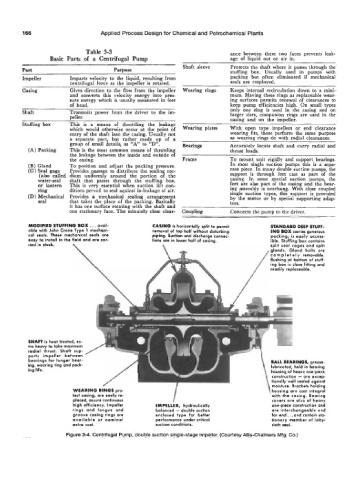

MODIFIED STUFFING BOX.. . avail- CASING is horizontally split to permit STANDARD DEEP STUFF-

able with John Crane Type 1 mechqni- removal of top half without disturbing ING BOX carries generous

tal seals. These mechanical seals are piping. Suction and discharge connec- packing; is easily access-

easy to install in the field and are car- tions are in lower half of casing. ible. Stuffing box contains

lied in stock. split seal cages and split

glonds. Gland bolts are

c o m p I e t e I y removable.

Bushing at bottom of stuff-

ing box is close fitting and

readily reploceable.

SHAFT is heat treated, ex-

tra heavy to take maximum

radial thrust. Shaft sup- /

ports impeller between

bearings for longer bear- ALL BEARINGS, grease-

ing, wearing ring and pack- ibricated, held in bearing

ing life. wring of heavy one-piece

/ mstruction - are excep-

Pnally well sealed against

housing are cost integral

WEARING RINGS pro- I \ moisture. Brackets holding

tect casing, are easily re- with the casing. Bearing

placed, assure continuous covers are also of heavy

high efficiency. Impeller IMPELLER, hydraulically one-piece construction and

rings and tongue and balanced - double suction are interchangeable end

groove casing rings are enclosed type for better for end.. . and contain sta-

available at nominal performance under critical tionary member of laby-

extra cost. suction conditions. rinth seal.

Figure 3-4. Centrifugal Pump, double suction single-stage impeller. (Courtesy Allis-Chalmers Mfg. Co.)