Page 194 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 194

Pumping of Liquids 167

Shaft CMANNEL RING

GLAND

Care should be given in selecting the shaft material. It

must be resistant to the corrosive action of the process flu-

ids, yet possess good strength characteristics for design.

For some designs it is preferable to use a shaft sleeve of

THRUST BEARING

SHAFTSLEEVE

I IMPELLERS

FLUID PASSAGES

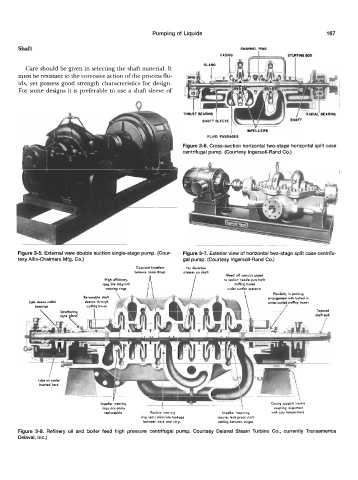

Figure 3-6. Cross-section horizontal two-stage horizontal split case

centrifugal pump. (Courtesy Ingersoll-Rand Co.)

Figure 3-5. External view double suction single-stage pump. (Cour- Figure 3-7. Exterior view of horizontal two-stage split case centrifu-

tesy Allis-Chalmers Mfg. Co.) gal pump. (Courtesy Ingersoll-Rand Co.)

Opposed Impollerr No distortion

balance axial thrust stresses on shoh

Bleed off annulus pip4

High efficiency, to suction nozzle puts both

long life labyrinth stuffing bores

wwring rings under sucRon pressure

\ Flexibility in packing

Figure 3-8. Refinery oil and boiler feed high pressure centrifugal pump. Courtesy Delaval Steam Turbine Co., currently Transamerica

Delaval, Inc.)