Page 195 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 195

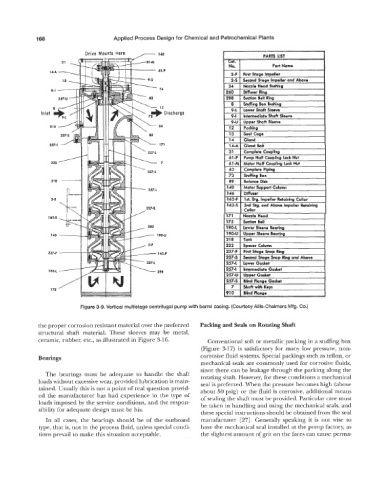

Drive Mounts Here -

168 Applied Process Design for Chemical and Petrochemical Plants

140

PARTS LIST

Lot.

~~ No. Part Name

2-F First Stage Impeller

2-S Second Stage Impeller and Above

34 Nozzle Head Bushing

260 Diffuser Ring

298 Suction Bell Ring

8 SMng Box Bushing

9-1 Lower Shaft Sleeve

ischarge

9-1 I Intermediate Shaft Sleeve I

9-U I Upper Shaft Sleeve

12 Packing

13 Seal Cage

14 Gland

14-A Gland Bolt

31 Complete Coupling

61 -P Pump Half Coupling Lack Nut

61 -M Motor Half Coupling Lack Nut

62 Complete Piping

73 Stuffing Box

89 Balance Disk

140 Motor Support Column

146 Diffuser

- 162-F 1 st. Stg. Impeller Retaining Collar

1624 2nd Stg. and Above Impeller Retaining

Collar

171 Nozzle Haad

175 I Sudion Ball I

190-1 Lower Sleeve Bearing

1904 Upper Sleeve Bearing

218 Tank

223 Spacer Column

237-F First Stage Snap Ring

237-5 Seeand Stage Snap Ring and Above

257-1 Lower Gasket

257-1 Intermediate Gasket

2574 Upper Gasket

257-5 Blind Flange Gasket

7 ShaftwithKeyr

1 75

910 Blind Flange

Figure 3-9. Vertical multistage centrifugal pump with barrel casing. (Courtesy Allis-Chalmers Mfg. Co.)

the proper corrosion resistant material over the preferred Packing and Seals on Rotating Shaft

structural shaft material. These sleeves may be metal,

ceramic, rubber, etc., as illustrated in Figure 3-16. Conventional soft or metallic packing in a stuffing box

(Figure 3-1’7) is satisfactory for many low pressure, non-

Bearings corrosive fluid systems. Special packings such as teflon, or

mechanical seals are commonly used for corrosive fluids,

since there can be leakage through the packing along the

The bearings must be adequate to handle the shaft rotating shaft. However, for these conditions a mechanical

loads without excessive wear, provided lubrication is main- seal is preferred. When the pressure becomes high (above

tained. Usually this is not a point of real question provid- about 50 psig) or the fluid is corrosive, additional means

ed the manufacturer has had experience in the type of of sealing the shaft must be provided. Particular care must

loads imposed by the service conditions, and the respon- be taken in handling and using the mechanical seals, and

sibility for adequate design must be his.

these special instructions should be obtained from the seal

In all cases, the bearings should be of the outboard manufacturer [27]. Generally speaking it is not wise to

type, that is, not in the process fluid, unless special condi- have the mechanical seal installed at the pump factory, as

tions prevail to make this situation acceptable. the slightest amount of grit on the faces can cause perma-