Page 197 - APPLIED PROCESS DESIGN FOR CHEMICAL AND PETROCHEMICAL PLANTS, Volume 1, 3rd Edition

P. 197

170 Applied Process Design for Chemical and Petrochemical Plants

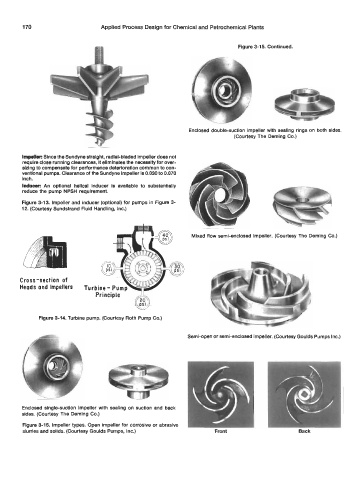

Figure 3-15. Continued.

Enclosed double-suction impeller with sealing rings on both sides.

(Courtesy The Deming Co.)

Irnpellec Since the Sundyne stralght, radlal-bladed Impeller does not

require close running clearances, It eliminates the necessity for over-

sizing to compensate for performance deterioration common to con-

ventional pumps. Clearance of the Sundyne Impeller Is 0.030 to 0.070

inch.

Inducer: An optlonal helical Inducer is available to substantially

reduce the pump NPSH requirement.

Figure 3-13. Impeller and inducer (optional) for pumps in Figure 3-

12. (Courtesy Sundstrand Fluid Handling, Inc.)

Mixed flow semi-enclosed impeller. (Courtesy The Deming Co.)

Cross-section of

Heads and Impellers

Principle -6

Figure 3-14. Turbine pump. (Courtesy Roth Pump Co.)

Semi-open or semi-enclosed impeller. (Courtesy Goulds Pumps Inc.)

Enclosed single-suction Impeller with sealing on suction and back

sides. (Courtesy The Deming Co.)

Figure 3-15. Impeller types. Open impeller for corrosive or abrasive

slurries and solids. (Courtesy Goulds Pumps, Inc.) Front Back