Page 148 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 148

Distillation 137

Area 0 -

Weir

\

inlet Downcomer Downcomer Note: Elliptical

(With or Without Shoves also used.

Weir or Seal BOX)

Cross -Flow Cross - Flow Cross- Flow

Inlet Downcorner Inlet Downcomer Inlet Downcomer

Boff le Weir

Outlet @ Downcomer

Cctlct Downcomer Outlet Dow'ncorner 'Weir

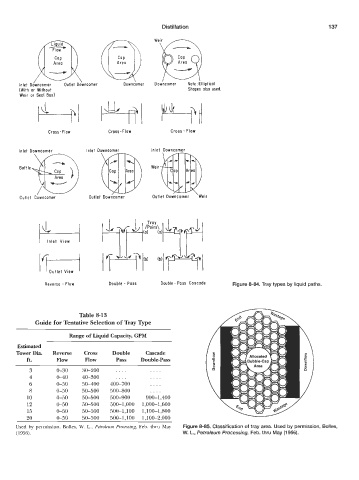

Reverse - Flow Double - Pass Double- Poss Cascade Figure 8-84. Tray types by liquid paths.

Table 8-13

Guide for Tentative Selection of Tray Type

Range of Liquid Capacity, GPM

Estimated

Tower Dia. Reverse Cross Double Cascade

ft. Flow Flow Pass Double-Pass

3 0-30 30-200 .... ....

4 0-40 40-300 .... ....

6 0-50 50-400 400-700 ....

8 0-50 50-500 500-800 ....

10 0-50 50-500 500-900 900-1,400

12 0-50 50-500 500-1,000 1,000-1,600

15 0-50 50-500 500-1,100 1,100-1,800

20 0-50 50-500 500-1,100 1,100-2,000

Used by permission, Bolles, W. L., Petroleum Procming, Feb. thru May Figure 8-85. Classification of tray area. Used by permission, Bolles,

(1956). W. L., Petroleum Processing, Feb. thru May (1956).