Page 143 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 143

1 32 Applied Process Design for Chemical and Petrochemical Plants

Figure 8-76. Type A-1 Ballast@ Tray. Used by Permission, Glitsch, Figure 8-77. Type V-1 Ballast@ Tray. Used by permission, Glitsch, Inc.

Inc.

b

Figure 8-78. Glitsch NyeTM Tray action to improve conventional sieve

and valve tray performance by 10-20%. Used by permission, Glitsch,

Inc., Bul. GLI-5138.

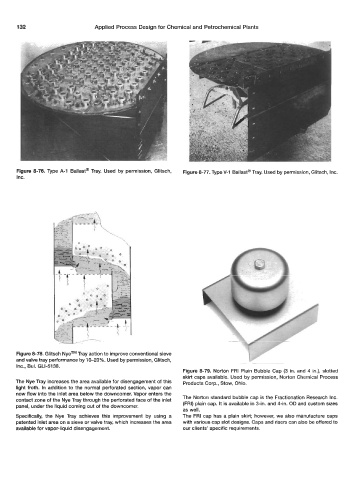

Figure 8-79. Norton FRI Plain Bubble Cap (3 in. and 4 in.), slotted

skirt caps available. Used by permission, Norton Chemical Process

The Nye Tray increases the area available for disengagement of this Products Corp., Stow, Ohio.

light froth. In addition to the normal perforated section, vapor can

now flow into the inlet area below the downcomer. Vapor enters the

contact zone of the Nye Tray through the perforated face of the inlet The Norton standard bubble cap is the Fractionation Research Inc.

panel, under the liquid coming out of the downcomer. (FRI) plain cap. It is available in 3-in. and 4-in. OD and custom sizes

as well.

Specifically, the Nye Tray achieves this improvement by using a The FRI cap has a plain skirt; however, we also manufacture caps

patented inlet area on a sieve or valve tray, which increases the area with various cap slot designs. Caps and risers can also be offered to

available for vapor-liquid disengagement. our clients' specific requirements.