Page 145 - Applied Process Design For Chemical And Petrochemical Plants Volume II

P. 145

134 Applied Process Design for Chemical and Petrochemical Plants

Cap Pitch Center to Center

Cap sizes 2-in., 3-in., and 4in.: recommended cap lane

distance of 1% in. (with Min. minimum, l%inch maxi-

mum) plus cap outside diameter.

For cap sizes of 6 and 8 in.: recommended cap lane dis-

tance of 1% in. (1%-in. minimum, 2?4in. maximum) plus

SPd cap outside diameter.

'Weld

Weirs

I Figure 8-100 is convenient for arriving at weir lengths

' %"a x 2%" Hex Head

relative to their effect on segmental downcomers.

metal washer

-- (a) Inlet

These contribute to the uniform distribution of liquid

as it enters the tray hm the downcomer. There are about

as many tray designs without weirs as with them. The

downcomer without inlet weir tends to maintain uniform

liquid distribution itself. The tray design with recessed seal

14 ga. cap

pan ensures against vapor backflow into the downcomer,

but this is seldom necessary. It is not recommended for

fluids that are dirty or tend to foul surfaces. The inlet weir

is objectionable for the same reason.

The first row of caps next to the weir or inlet downcomer

must be set back far enough to prevent bubbling into the

downcomer. The inlet weir prevents this, although it can be

Detail of Pressed properly handled by leaving about 3 in. between inlet down-

Cap and Riser comer and the nearest face of the first row of caps.

Scale: 314" = 1 I'

The height of an inlet weir, ifused, should be 1 to 1% in.

above the top of the slots of the bubble caps when

installed on the tray.

If inlet weirs are used they should have at least two slots

dots

%in. by 1-in. flush with the tray floor to aid in flushing out

any trapped sediment or other material. There should also

be weep or drain holes below the downcomer to drain the

weir seal area. The size should be set by the type of service,

but a minimum of %in. is recommended.

Detail of Slots (b) Outlet

Pressed Cap

=

scale: I" 1" These are necessary to maintain seal on the tray, thus

ensuring bubbling of vapors through liquid. The lower the

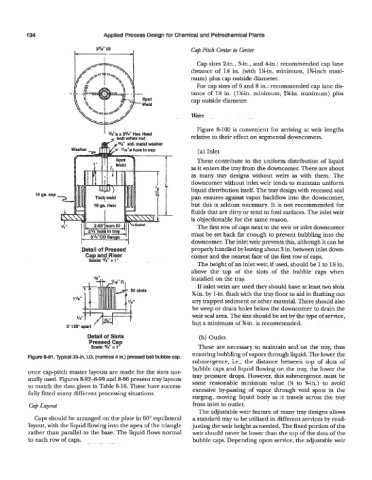

Figure 881. Typical 3Mn. I.D. (nominal 4 in.) pressed bell bubble cap.

submergence, i.e., the distance between top of slots of

bubble caps and liquid flowing on the tray, the lower the

once cap-pitch master layouts are made for the sizes nor- tray pressure drops. However, this submergence must be

mally used. Figures 8-92-8-99 and 8-86 present tray layouts some reasonable minimum value (V, to %in.) to avoid

to match the data given in Table 8-16. These have success-

fully fitted many different processing situations. excessive by-passing of vapor through void spots in the

surging, moving liquid body as it travels across the tray

Cap Laput from inlet to outlet

The adjustable weir feature of many tray designs allows

Caps should be arranged on the plate in 60" equilateral a standard tray to be utilized in different services by read-

layout, with the liquid flowing into the apex of the triangle justing the weir height as needed. The fmed portion of the

rather than parallel to the base. The liquid flows normal weir should never be lower than the top of the slots of the

to each row of caps. bubble caps. Depending upon service, the adjustable weir