Page 127 - 05. Subyek Teknik Mesin - Automobile Mechanical and Electrical Systems Automotive Technology Vehicle Maintenance and Repair (Vehicle Maintenance Repr Nv2) by Tom Denton

P. 127

2

Engine systems 111

Wet liner Dry liner

1 2

1

4

2

3

3

1 Liner 1 Liner

2 Sealing ring 2 Coolant

3 Coolant 3 Cylinder block

4 Cylinder block

Figure 2.53 Wet and dry liners

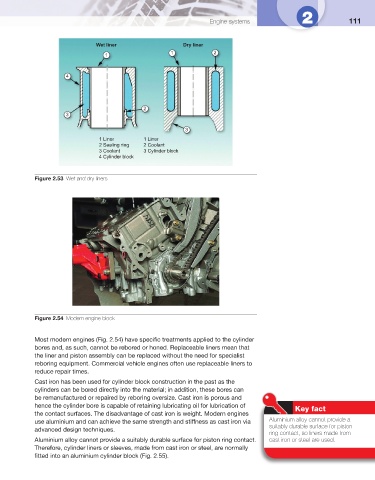

Figure 2.54 Modern engine block

Most modern engines ( Fig. 2.54 ) have specifi c treatments applied to the cylinder

bores and, as such, cannot be rebored or honed. Replaceable liners mean that

the liner and piston assembly can be replaced without the need for specialist

reboring equipment. Commercial vehicle engines often use replaceable liners to

reduce repair times.

Cast iron has been used for cylinder block construction in the past as the

cylinders can be bored directly into the material; in addition, these bores can

be remanufactured or repaired by reboring oversize. Cast iron is porous and

hence the cylinder bore is capable of retaining lubricating oil for lubrication of

Key fact

the contact surfaces. The disadvantage of cast iron is weight. Modern engines

use aluminium and can achieve the same strength and stiffness as cast iron via Aluminium alloy cannot provide a

suitably durable surface for piston

advanced design techniques.

ring contact, so liners made from

Aluminium alloy cannot provide a suitably durable surface for piston ring contact. cast iron or steel are used.

Therefore, cylinder liners or sleeves, made from cast iron or steel, are normally

fi tted into an aluminium cylinder block ( Fig. 2.55 ).