Page 128 - 05. Subyek Teknik Mesin - Automobile Mechanical and Electrical Systems Automotive Technology Vehicle Maintenance and Repair (Vehicle Maintenance Repr Nv2) by Tom Denton

P. 128

2

112 Automobile mechanical and electrical systems

Figure 2.55 Liners in an aluminium block

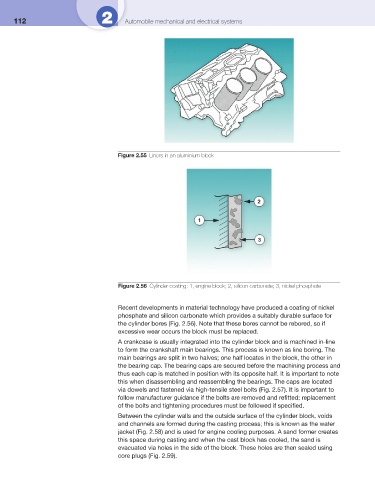

Figure 2.56 Cylinder coating: 1, engine block; 2, silicon carbonate; 3, nickel phosphate

Recent developments in material technology have produced a coating of nickel

phosphate and silicon carbonate which provides a suitably durable surface for

the cylinder bores ( Fig. 2.56 ). Note that these bores cannot be rebored, so if

excessive wear occurs the block must be replaced.

A crankcase is usually integrated into the cylinder block and is machined in-line

to form the crankshaft main bearings. This process is known as line boring. The

main bearings are split in two halves; one half locates in the block, the other in

the bearing cap. The bearing caps are secured before the machining process and

thus each cap is matched in position with its opposite half. It is important to note

this when disassembling and reassembling the bearings. The caps are located

via dowels and fastened via high-tensile steel bolts ( Fig. 2.57 ). It is important to

follow manufacturer guidance if the bolts are removed and refi tted; replacement

of the bolts and tightening procedures must be followed if specifi ed.

Between the cylinder walls and the outside surface of the cylinder block, voids

and channels are formed during the casting process; this is known as the water

jacket ( Fig. 2.58 ) and is used for engine cooling purposes. A sand former creates

this space during casting and when the cast block has cooled, the sand is

evacuated via holes in the side of the block. These holes are then sealed using

core plugs ( Fig. 2.59 ).