Page 145 - 05. Subyek Teknik Mesin - Automobile Mechanical and Electrical Systems Automotive Technology Vehicle Maintenance and Repair (Vehicle Maintenance Repr Nv2) by Tom Denton

P. 145

2

Engine systems 129

Figure 2.95 Seat angles: 1, head; 2, valve seat; 3, possible angles; 4, valve insert angle where

contact is made

1 2 3

7 4

8

5

9 6

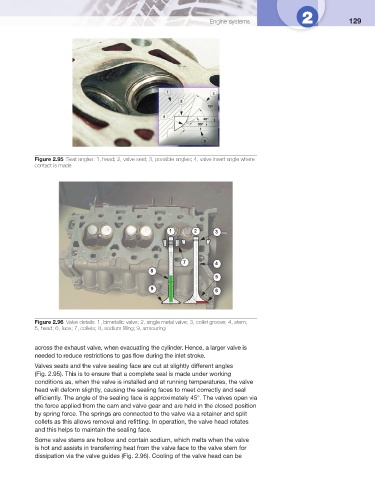

Figure 2.96 Valve details: 1, bimetallic valve; 2, single metal valve; 3, collet groove; 4, stem;

5, head; 6, face; 7, collets; 8, sodium fi lling; 9, armouring

across the exhaust valve, when evacuating the cylinder. Hence, a larger valve is

needed to reduce restrictions to gas fl ow during the inlet stroke.

Valves seats and the valve sealing face are cut at slightly different angles

( Fig. 2.95 ). This is to ensure that a complete seal is made under working

conditions as, when the valve is installed and at running temperatures, the valve

head will deform slightly, causing the sealing faces to meet correctly and seal

effi ciently. The angle of the sealing face is approximately 45°. The valves open via

the force applied from the cam and valve gear and are held in the closed position

by spring force. The springs are connected to the valve via a retainer and split

collets as this allows removal and refi tting. In operation, the valve head rotates

and this helps to maintain the sealing face.

Some valve stems are hollow and contain sodium, which melts when the valve

is hot and assists in transferring heat from the valve face to the valve stem for

dissipation via the valve guides ( Fig. 2.96 ). Cooling of the valve head can be