Page 206 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 206

CH AP TER 8 .1 Types of suspension and drive

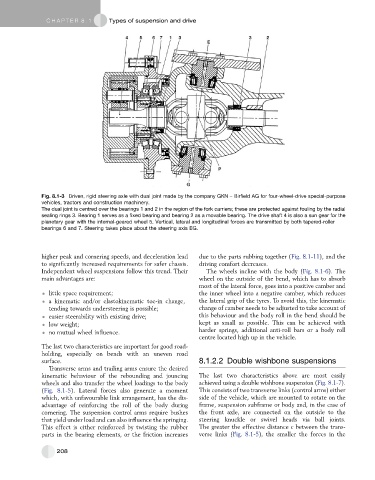

Fig. 8.1-3 Driven, rigid steering axle with dual joint made by the company GKN – Birfield AG for four-wheel-drive special-purpose

vehicles, tractors and construction machinery.

The dual joint is centred over the bearings 1 and 2 in the region of the fork carriers; these are protected against fouling by the radial

sealing rings 3. Bearing 1 serves as a fixed bearing and bearing 2 as a movable bearing. The drive shaft 4 is also a sun gear for the

planetary gear with the internal-geared wheel 5. Vertical, lateral and longitudinal forces are transmitted by both tapered-roller

bearings 6 and 7. Steering takes place about the steering axis EG.

higher peak and cornering speeds, and deceleration lead due to the parts rubbing together (Fig. 8.1-11), and the

to significantly increased requirements for safer chassis. driving comfort decreases.

Independent wheel suspensions follow this trend. Their The wheels incline with the body (Fig. 8.1-6). The

main advantages are: wheel on the outside of the bend, which has to absorb

most of the lateral force, goes into a positive camber and

little space requirement; the inner wheel into a negative camber, which reduces

a kinematic and/or elastokinematic toe-in change, the lateral grip of the tyres. To avoid this, the kinematic

tending towards understeering is possible; change of camber needs to be adjusted to take account of

easier steerability with existing drive; this behaviour and the body roll in the bend should be

low weight; kept as small as possible. This can be achieved with

no mutual wheel influence. harder springs, additional anti-roll bars or a body roll

centre located high up in the vehicle.

The last two characteristics are important for good road-

holding, especially on bends with an uneven road

surface. 8.1.2.2 Double wishbone suspensions

Transverse arms and trailing arms ensure the desired

kinematic behaviour of the rebounding and jouncing The last two characteristics above are most easily

wheels and also transfer the wheel loadings to the body achieved using a double wishbone suspension (Fig. 8.1-7).

(Fig. 8.1-5). Lateral forces also generate a moment This consists of two transverse links (control arms) either

which, with unfavourable link arrangement, has the dis- side of the vehicle, which are mounted to rotate on the

advantage of reinforcing the roll of the body during frame, suspension subframe or body and, in the case of

cornering. The suspension control arms require bushes the front axle, are connected on the outside to the

that yield under load and can also influence the springing. steering knuckle or swivel heads via ball joints.

This effect is either reinforced by twisting the rubber The greater the effective distance c between the trans-

parts in the bearing elements, or the friction increases verse links (Fig. 8.1-5), the smaller the forces in the

208