Page 207 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 207

Types of suspension and drive CHAPTER 8.1

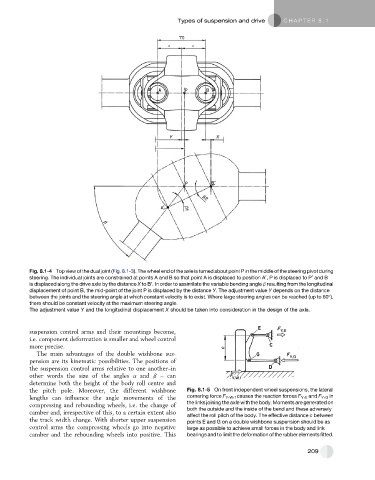

Fig. 8.1-4 Top view of the dual joint (Fig. 8.1-3). The wheel end of the axle is turned about point P in the middle of the steering pivot during

0

0

steering. The individual joints are constrained at points A and B so that point A is displaced to position A , P is displaced to P and B

0

is displaced along the drive axle by the distance X to B . In order to assimilate the variable bending angle b resulting from the longitudinal

displacement of point B, the mid-point of the joint P is displaced by the distance Y. The adjustment value Y depends on the distance

between the joints and the steering angle at which constant velocity is to exist. Where large steering angles can be reached (up to 60 ),

there should be constant velocity at the maximum steering angle.

The adjustment value Y and the longitudinal displacement X should be taken into consideration in the design of the axle.

suspension control arms and their mountings become,

i.e. component deformation is smaller and wheel control

more precise.

The main advantages of the double wishbone sus-

pension are its kinematic possibilities. The positions of

the suspension control arms relative to one another–in

other words the size of the angles a and b – can

determine both the height of the body roll centre and

the pitch pole. Moreover, the different wishbone Fig. 8.1-5 On front independent wheel suspensions, the lateral

lengths can influence the angle movements of the cornering force F Y , W , f causes the reaction forces F Y , E and F Y , G in

the links joining the axle with the body. Moments are generated on

compressing and rebounding wheels, i.e. the change of

camber and, irrespective of this, to a certain extent also both the outside and the inside of the bend and these adversely

affect the roll pitch of the body. The effective distance c between

the track width change. With shorter upper suspension points E and G on a double wishbone suspension should be as

control arms the compressing wheels go into negative large as possible to achieve small forces in the body and link

camber and the rebounding wheels into positive. This bearings and to limit the deformation of the rubber elements fitted.

209