Page 231 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 231

Types of suspension and drive CHAPTER 8.1

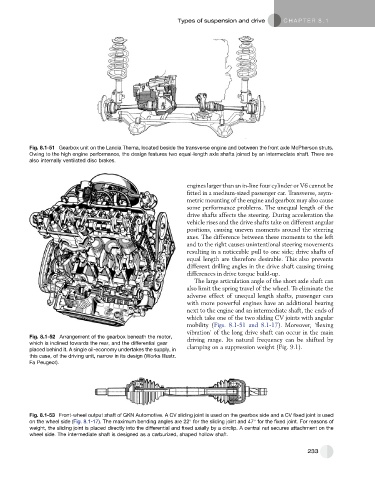

Fig. 8.1-51 Gearbox unit on the Lancia Thema, located beside the transverse engine and between the front axle McPherson struts.

Owing to the high engine performance, the design features two equal-length axle shafts joined by an intermediate shaft. There are

also internally ventilated disc brakes.

engines larger than an in-line four cylinder or V6 cannot be

fitted in a medium-sized passenger car. Transverse, asym-

metric mounting of the engine and gearbox may also cause

some performance problems. The unequal length of the

drive shafts affects the steering. During acceleration the

vehicle rises and the drive shafts take on different angular

positions, causing uneven moments around the steering

axes. The difference between these moments to the left

and to the right causes unintentional steering movements

resulting in a noticeable pull to one side; drive shafts of

equal length are therefore desirable. This also prevents

different drilling angles in the drive shaft causing timing

differences in drive torque build-up.

The large articulation angle of the short axle shaft can

also limit the spring travel of the wheel. To eliminate the

adverse effect of unequal length shafts, passenger cars

with more powerful engines have an additional bearing

next to the engine and an intermediate shaft, the ends of

which take one of the two sliding CV joints with angular

mobility (Figs. 8.1-51 and 8.1-17). Moreover, ’flexing

vibration’ of the long drive shaft can occur in the main

Fig. 8.1-52 Arrangement of the gearbox beneath the motor, driving range. Its natural frequency can be shifted by

which is inclined towards the rear, and the differential gear

placed behind it. A single oil-economy undertakes the supply, in clamping on a suppression weight (Fig. 9.1).

this case, of the driving unit, narrow in its design (Works Illustr.

Fa Peugeot).

Fig. 8.1-53 Front-wheel output shaft of GKN Automotive. A CV sliding joint is used on the gearbox side and a CV fixed joint is used

on the wheel side (Fig. 8.1-17). The maximum bending angles are 22 for the sliding joint and 47 for the fixed joint. For reasons of

weight, the sliding joint is placed directly into the differential and fixed axially by a circlip. A central nut secures attachment on the

wheel side. The intermediate shaft is designed as a carburized, shaped hollow shaft.

233