Page 227 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 227

Types of suspension and drive CHAPTER 8.1

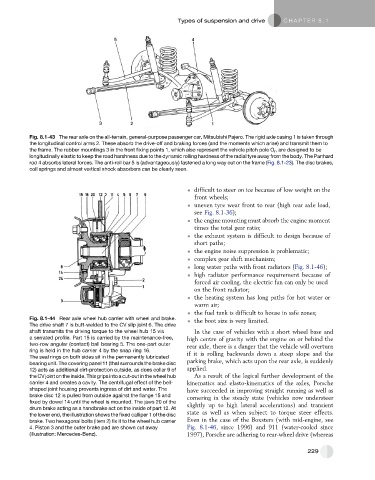

Fig. 8.1-43 The rear axle on the all-terrain, general-purpose passenger car, Mitsubishi Pajero. The rigid axle casing 1 is taken through

the longitudinal control arms 2. These absorb the drive-off and braking forces (and the moments which arise) and transmit them to

the frame. The rubber mountings 3 in the front fixing points 1, which also represent the vehicle pitch pole O r , are designed to be

longitudinally elastic to keep the road harshness due to the dynamic rolling hardness of the radial tyre away from the body. The Panhard

rod 4 absorbs lateral forces. The anti-roll bar 5 is (advantageously) fastened a long way out on the frame (Fig. 8.1-23). The disc brakes,

coil springs and almost vertical shock absorbers can be clearly seen.

difficult to steer on ice because of low weight on the

front wheels;

uneven tyre wear front to rear (high rear axle load,

see Fig. 8.1-36);

the engine mounting must absorb the engine moment

times the total gear ratio;

the exhaust system is difficult to design because of

short paths;

the engine noise suppression is problematic;

complex gear shift mechanism;

long water paths with front radiators (Fig. 8.1-46);

high radiator performance requirement because of

forced air cooling, the electric fan can only be used

on the front radiator;

the heating system has long paths for hot water or

warm air;

the fuel tank is difficult to house in safe zones;

Fig. 8.1-44 Rear axle wheel hub carrier with wheel and brake. the boot size is very limited.

The drive shaft 7 is butt-welded to the CV slip joint 6. The drive

shaft transmits the driving torque to the wheel hub 15 via In the case of vehicles with a short wheel base and

a serrated profile. Part 15 is carried by the maintenance-free, high centre of gravity with the engine on or behind the

two-row angular (contact) ball bearing 5. The one-part outer rear axle, there is a danger that the vehicle will overturn

ring is held in the hub carrier 4 by the snap ring 16. if it is rolling backwards down a steep slope and the

The seal rings on both sides sit in the permanently lubricated

parking brake, which acts upon the rear axle, is suddenly

bearing unit. The covering panel 11 (that surrounds the brake disc

12) acts as additional dirt-protection outside, as does collar 9 of applied.

the CV joint on the inside. This grips into a cut-out in the wheel hub As a result of the logical further development of the

carrier 4 and creates a cavity. The centrifugal effect of the bell- kinematics and elasto-kinematics of the axles, Porsche

shaped joint housing prevents ingress of dirt and water. The have succeeded in improving straight running as well as

brake disc 12 is pulled from outside against the flange 15 and cornering in the steady state (vehicles now understeer

fixed by dowel 14 until the wheel is mounted. The jaws 20 of the

slightly up to high lateral accelerations) and transient

drum brake acting as a handbrake act on the inside of part 12. At

the lower end, the illustration shows the fixed calliper 1 of the disc state as well as when subject to torque steer effects.

brake. Two hexagonal bolts (item 2) fix it to the wheel hub carrier Even in the case of the Boxsters (with mid-engine, see

4. Piston 3 and the outer brake pad are shown cut away Fig. 8.1-46, since 1996) and 911 (water-cooled since

(illustration: Mercedes-Benz). 1997), Porsche are adhering to rear-wheel drive (whereas

229