Page 223 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 223

Types of suspension and drive CHAPTER 8.1

A long exhaust system with good silencing and cata-

lytic converter configuration.

Good front crumple zone, together with the

‘submarining’ power plant unit, i.e. one that goes

underneath the floor panel during frontal collision.

Simple and varied front axle designs are possible irre-

spective of drive forces.

More even tyre wear thanks to function distribution

of steering/drive.

Uncomplicated gear shift mechanism.

Optimum gearbox efficiency in direct gear because

no force-transmitting bevel gear is in action.

Sufficient space for housing the steering system in

the case of a recirculating ball steering gear.

Good cooling because the engine and radiator are at

the front; a power-saving fan can be fitted.

Effective heating due to short hot-air and water paths.

The following disadvantages mean that, in recent years,

only a few saloon cars under 2 l engine displacement

have been launched internationally using this design,

and performance cars also featured the front-mounted

design:

Unstable straight-running ability (Fig. 8.1-35), which

can be fully corrected by special front suspension

geometry settings, appropriate rear axle design and

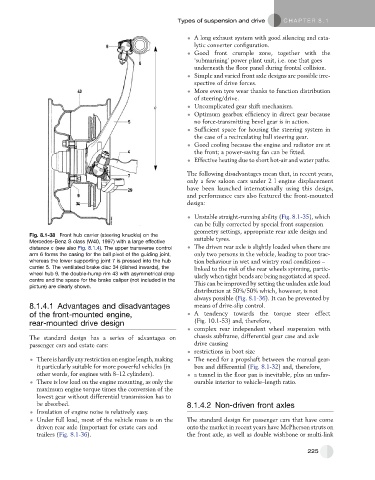

Fig. 8.1-38 Front hub carrier (steering knuckle) on the

Mercedes-Benz S class (W40, 1997) with a large effective suitable tyres.

distance c (see also Fig. 8.1.4). The upper transverse control The driven rear axle is slightly loaded when there are

arm 6 forms the casing for the ball pivot of the guiding joint, only two persons in the vehicle, leading to poor trac-

whereas the lower supporting joint 7 is pressed into the hub tion behaviour in wet and wintry road conditions –

carrier 5. The ventilated brake disc 34 (dished inwards), the linked to the risk of the rear wheels spinning, partic-

wheel hub 9, the double-hump rim 43 with asymmetrical drop ularly when tight bends are being negotiated at speed.

centre and the space for the brake caliper (not included in the This can be improved by setting the unladen axle load

picture) are clearly shown.

distribution at 50%/50% which, however, is not

always possible (Fig. 8.1-36). It can be prevented by

8.1.4.1 Advantages and disadvantages means of drive-slip control.

of the front-mounted engine, A tendency towards the torque steer effect

rear-mounted drive design (Fig. 10.1-53) and, therefore,

complex rear independent wheel suspension with

The standard design has a series of advantages on chassis subframe, differential gear case and axle

passenger cars and estate cars: drive causing

restrictions in boot size

Thereishardlyanyrestrictiononenginelength,making The need for a propshaft between the manual gear-

it particularly suitable for more powerful vehicles (in box and differential (Fig. 8.1-32) and, therefore,

other words, for engines with 8–12 cylinders). a tunnel in the floor pan is inevitable, plus an unfav-

There is low load on the engine mounting, as only the ourable interior to vehicle–length ratio.

maximum engine torque times the conversion of the

lowest gear without differential transmission has to

be absorbed. 8.1.4.2 Non-driven front axles

Insulation of engine noise is relatively easy.

Under full load, most of the vehicle mass is on the The standard design for passenger cars that have come

driven rear axle (important for estate cars and onto the market in recent years have McPherson struts on

trailers (Fig. 8.1-36). the front axle, as well as double wishbone or multi-link

225