Page 221 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 221

Types of suspension and drive CHAPTER 8.1

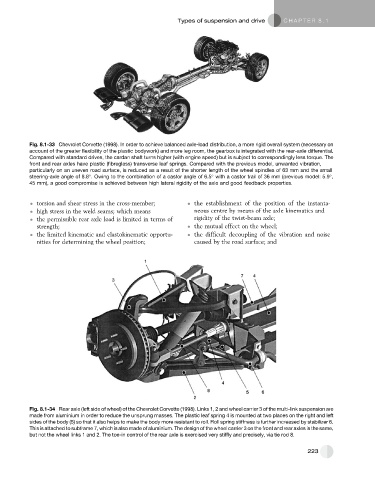

Fig. 8.1-33 Chevrolet Corvette (1998). In order to achieve balanced axle-load distribution, a more rigid overall system (necessary on

account of the greater flexibility of the plastic bodywork) and more leg room, the gearbox is integrated with the rear-axle differential.

Compared with standard drives, the cardan shaft turns higher (with engine speed) but is subject to correspondingly less torque. The

front and rear axles have plastic (fibreglass) transverse leaf springs. Compared with the previous model, unwanted vibration,

particularly on an uneven road surface, is reduced as a result of the shorter length of the wheel spindles of 63 mm and the small

steering-axle angle of 8.8 . Owing to the combination of a castor angle of 6.5 with a castor trail of 36 mm (previous model: 5.9 ,

45 mm), a good compromise is achieved between high lateral rigidity of the axle and good feedback properties.

torsion and shear stress in the cross-member; the establishment of the position of the instanta-

high stress in the weld seams; which means neous centre by means of the axle kinematics and

the permissible rear axle load is limited in terms of rigidity of the twist-beam axle;

strength; the mutual effect on the wheel;

the limited kinematic and elastokinematic opportu- the difficult decoupling of the vibration and noise

nities for determining the wheel position; caused by the road surface; and

Fig. 8.1-34 Rear axle (left side of wheel) of the Chevrolet Corvette (1998). Links 1, 2 and wheel carrier 3 of the multi-link suspension are

made from aluminium in order to reduce the unsprung masses. The plastic leaf spring 4 is mounted at two places on the right and left

sides of the body (5) so that it also helps to make the body more resistant to roll. Roll spring stiffness is further increased by stabilizer 6.

This is attached to subframe 7, which is also made of aluminium. The design of the wheel carrier 3 on the front and rear axles is the same,

but not the wheel links 1 and 2. The toe-in control of the rear axle is exercised very stiffly and precisely, via tie rod 8.

223