Page 226 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 226

CH AP TER 8 .1 Types of suspension and drive

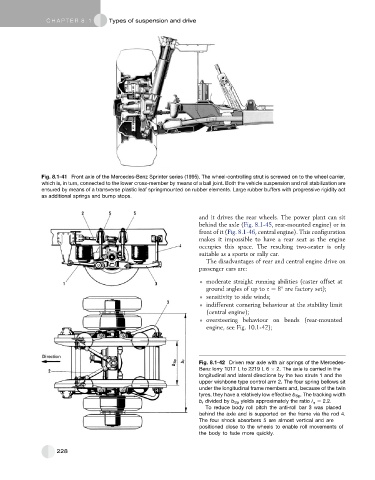

Fig. 8.1-41 Front axle of the Mercedes-Benz Sprinter series (1995). The wheel-controlling strut is screwed on to the wheel carrier,

which is, in turn, connected to the lower cross-member by means of a ball joint. Both the vehicle suspension and roll stabilization are

ensured by means of a transverse plastic leaf springmounted on rubber elements. Large rubber buffers with progressive rigidity act

as additional springs and bump stops.

and it drives the rear wheels. The power plant can sit

behind the axle (Fig. 8.1-45, rear-mounted engine) or in

front of it (Fig. 8.1-46, central engine). This configuration

makes it impossible to have a rear seat as the engine

occupies this space. The resulting two-seater is only

suitable as a sports or rally car.

The disadvantages of rear and central engine drive on

passenger cars are:

moderate straight running abilities (caster offset at

ground angles of up to s ¼ 8 are factory set);

sensitivity to side winds;

indifferent cornering behaviour at the stability limit

(central engine);

oversteering behaviour on bends (rear-mounted

engine, see Fig. 10.1-42);

Fig. 8.1-42 Driven rear axle with air springs of the Mercedes-

Benz lorry 1017 L to 2219 L 6 2. The axle is carried in the

longitudinal and lateral directions by the two struts 1 and the

upper wishbone type control arm 2. The four spring bellows sit

under the longitudinal frame members and, because of the twin

tyres, they have a relatively low effective b Sp . The tracking width

b r divided by b Sp yields approximately the ratio i 4 ¼ 2.2.

To reduce body roll pitch the anti-roll bar 3 was placed

behind the axle and is supported on the frame via the rod 4.

The four shock absorbers 5 are almost vertical and are

positioned close to the wheels to enable roll movements of

the body to fade more quickly.

228