Page 604 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 604

Design and material utilization C HAPTER 18.1

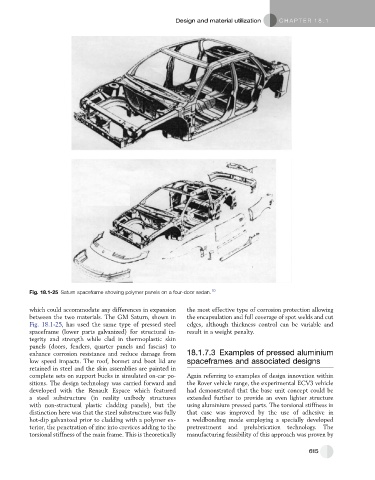

Fig. 18.1-25 Saturn spaceframe showing polymer panels on a four-door sedan. 10

which could accommodate any differences in expansion the most effective type of corrosion protection allowing

between the two materials. The GM Saturn, shown in the encapsulation and full coverage of spot welds and cut

Fig. 18.1-25, has used the same type of pressed steel edges, although thickness control can be variable and

spaceframe (lower parts galvanized) for structural in- result in a weight penalty.

tegrity and strength while clad in thermoplastic skin

panels (doors, fenders, quarter panels and fascias) to

enhance corrosion resistance and reduce damage from 18.1.7.3 Examples of pressed aluminium

low speed impacts. The roof, bonnet and boot lid are spaceframes and associated designs

retained in steel and the skin assemblies are painted in

complete sets on support bucks in simulated on-car po- Again referring to examples of design innovation within

sitions. The design technology was carried forward and the Rover vehicle range, the experimental ECV3 vehicle

developed with the Renault Espace which featured had demonstrated that the base unit concept could be

a steel substructure (in reality unibody structures extended further to provide an even lighter structure

with non-structural plastic cladding panels), but the using aluminium pressed parts. The torsional stiffness in

distinction here was that the steel substructure was fully that case was improved by the use of adhesive in

hot-dip galvanized prior to cladding with a polymer ex- a weldbonding mode employing a specially developed

terior, the penetration of zinc into crevices adding to the pretreatment and prelubrication technology. The

torsional stiffness of the main frame. This is theoretically manufacturing feasibility of this approach was proven by

615