Page 605 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 605

CHAP TER 1 8. 1 Design and material utilization

assemblies and dashboard fascia. Repair is considered

with a replacement composite crash structure at the

front and a mechanically fastened subframe at the rear

onto which the rear suspension is mounted. In the case of

major frame damage the complete spaceframe can also

be replaced. The choice of alloys for extrusions and sheet

is influenced by ease of recycling.

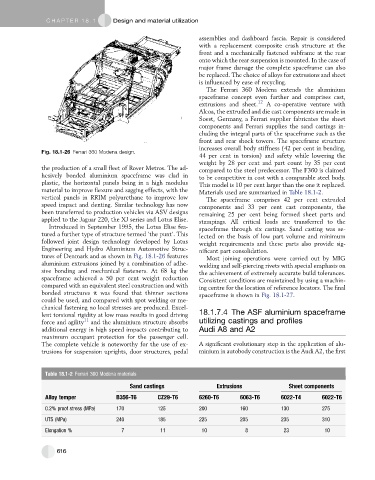

The Ferrari 360 Modena extends the aluminium

spaceframe concept even further and comprises cast,

extrusions and sheet. 12 A co-operative venture with

Alcoa, the extruded and die cast components are made in

Soest, Germany, a Ferrari supplier fabricates the sheet

components and Ferrari supplies the sand castings in-

cluding the integral parts of the spaceframe such as the

front and rear shock towers. The spaceframe structure

increases overall body stiffness (42 per cent in bending,

Fig. 18.1-26 Ferrari 360 Modena design.

44 per cent in torsion) and safety while lowering the

weight by 28 per cent and part count by 35 per cent

the production of a small fleet of Rover Metros. The ad- compared to the steel predecessor. The F360 is claimed

hesively bonded aluminium spaceframe was clad in to be competitive in cost with a comparable steel body.

plastic, the horizontal panels being in a high modulus This model is 10 per cent larger than the one it replaced.

material to improve flexure and sagging effects, with the Materials used are summarized in Table 18.1-2.

vertical panels in RRIM polyurethane to improve low The spaceframe comprises 42 per cent extruded

speed impact and denting. Similar technology has now components and 33 per cent cast components, the

been transferred to production vehicles via ASV designs remaining 25 per cent being formed sheet parts and

applied to the Jaguar 220, the XJ series and Lotus Elise. stampings. All critical loads are transferred to the

Introduced in September 1995, the Lotus Elise fea- spaceframe through six castings. Sand casting was se-

tured a further type of structure termed ‘the punt’. This lected on the basis of low part volume and minimum

followed joint design technology developed by Lotus weight requirements and these parts also provide sig-

Engineering and Hydro Aluminium Automotive Struc- nificant part consolidation.

tures of Denmark and as shown in Fig. 18.1-26 features Most joining operations were carried out by MIG

aluminium extrusions joined by a combination of adhe- welding and self-piercing rivets with special emphasis on

sive bonding and mechanical fasteners. At 68 kg the the achievement of extremely accurate build tolerances.

spaceframe achieved a 50 per cent weight reduction Consistent conditions are maintained by using a machin-

compared with an equivalent steel construction and with ing centre for the location of reference locators. The final

bonded structures it was found that thinner sections spaceframe is shown in Fig. 18.1-27.

could be used, and compared with spot welding or me-

chanical fastening no local stresses are produced. Excel-

lent torsional rigidity at low mass results in good driving 18.1.7.4 The ASF aluminium spaceframe

force and agility 11 and the aluminium structure absorbs utilizing castings and profiles

additional energy in high speed impacts contributing to Audi A8 and A2

maximum occupant protection for the passenger cell.

The complete vehicle is noteworthy for the use of ex- A significant evolutionary step in the application of alu-

trusions for suspension uprights, door structures, pedal minium in autobody construction is the Audi A2, the first

Table 18.1-2 Ferrari 360 Modena materials

Sand castings Extrusions Sheet components

Alloy temper B356-T6 CZ29-T6 6260-T6 6063-T6 6022-T4 6022-T6

0.2% proof stress (MPa) 170 125 200 160 130 275

UTS (MPa) 240 185 225 205 235 310

Elongation % 7 11 10 8 23 10

616