Page 607 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 607

CHAP TER 1 8. 1 Design and material utilization

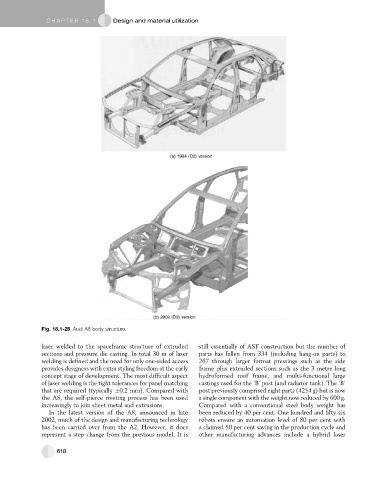

Fig. 18.1-28 Audi A8 body structure.

laser welded to the spaceframe structure of extruded still essentially of ASF construction but the number of

sections and pressure die casting. In total 30 m of laser parts has fallen from 334 (including hang-on parts) to

welding is defined and the need for only one-sided access 267 through larger format pressings such as the side

provides designers with extra styling freedom at the early frame plus extruded sections such as the 3 metre long

concept stage of development. The most difficult aspect hydroformed roof frame, and multi-functional large

of laser welding is the tight tolerances for panel matching castings used for the ‘B’ post (and radiator tank). The ‘B’

that are required (typically 0.2 mm). Compared with post previously comprised eight parts (4254 g) but is now

the A8, the self-pierce riveting process has been used a single component with the weight now reduced by 600 g.

increasingly to join sheet metal and extrusions. Compared with a conventional steel body weight has

In the latest version of the A8, announced in late been reduced by 40 per cent. One hundred and fifty-six

2002, much of the design and manufacturing technology robots ensure an automation level of 80 per cent with

has been carried over from the A2. However, it does a claimed 50 per cent saving in the production cycle and

represent a step change from the previous model. It is other manufacturing advances include a hybrid laser

618