Page 612 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 612

Design and material utilization C HAPTER 18.1

Body structure layer

Creative Application Focussing Confirmation

direction application of application

Component

Materials

System

Tooling & Forming

Assembly

Highlight main Generic Concept levels

issues application

Gateway 0 Apply to product

(a)

Package and performance attributes

Conventional Hydroformed radii

100% 84% 10 mm

Flange

16 mm

Circumference 447 mm Circumference 383 mm

Sectional benefits from hydroforming

Hydroformed

section Opportunity to employ

the additional package

Conventional space to increase the

press formed size of the section

section

Springback comparison

6 mm 20 mm

Ideal geometry Mild steel High strength steel

St 140 ZSt 260

Maximum deflection with hydroformed

components indicates 0.2 mm deflection

(b)

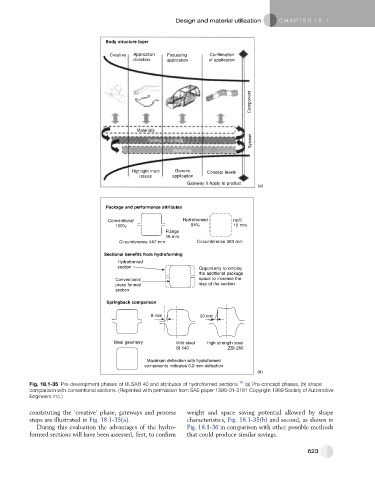

Fig. 18.1-35 Pre-development phases of ULSAB 40 and attributes of hydroformed sections. 16 (a) Pre-concept phases, (b) shape

comparison with conventional sections. (Reprinted with permission from SAE paper 1999-01-3181 Copyright 1999 Society of Automotive

Engineers Inc.)

constituting the ‘creative’ phase, gateways and process weight and space saving potential allowed by shape

steps are illustrated in Fig. 18.1-35(a). characteristics, Fig. 18.1-35(b) and second, as shown in

During this evaluation the advantages of the hydro- Fig. 18.1-36 in comparison with other possible methods

formed sections will have been assessed, first, to confirm that could produce similar savings.

623