Page 615 - Automotive Engineering Powertrain Chassis System and Vehicle Body

P. 615

CHAP TER 1 8. 1 Design and material utilization

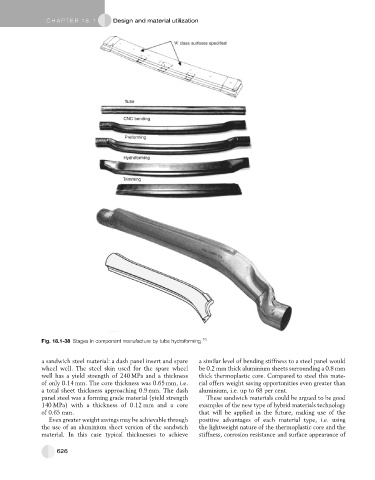

Fig. 18.1-38 Stages in component manufacture by tube hydroforming. 16

a sandwich steel material: a dash panel insert and spare a similar level of bending stiffness to a steel panel would

wheel well. The steel skin used for the spare wheel be 0.2 mm thick aluminium sheets surrounding a 0.8 mm

well has a yield strength of 240 MPa and a thickness thick thermoplastic core. Compared to steel this mate-

of only 0.14 mm. The core thickness was 0.65 mm, i.e. rial offers weight saving opportunities even greater than

a total sheet thickness approaching 0.9 mm. The dash aluminium, i.e. up to 68 per cent.

panel steel was a forming grade material (yield strength These sandwich materials could be argued to be good

140 MPa) with a thickness of 0.12 mm and a core examples of the new type of hybrid materials technology

of 0.65 mm. that will be applied in the future, making use of the

Even greater weight savings may be achievable through positive advantages of each material type, i.e. using

the use of an aluminium sheet version of the sandwich the lightweight nature of the thermoplastic core and the

material. In this case typical thicknesses to achieve stiffness, corrosion resistance and surface appearance of

626