Page 381 - Biaxial Multiaxial Fatigue and Fracture

P. 381

The Environment Effect on Fatigue Crack Growth Rates in 7049 Aluminium Alloy at __. 365

(b), represents pure or ideal fatigue crack growth, and this forms the reference line for the

ideal inert behaviour which is the basis for the environment contributions [48]. This ideal

behaviour appears only if the vacuum is very high or impurities in the so-called inert

environments are very low or the material is non-reactive to a given environment. Deviation

from the ideal line occurs if the crack pwth mechanism changes.

In principle, K,,, or its non-linear equivalent is essential for all fracture process involving

creation of two new surfaces. For monotonic fracture, this parameter reduces to KIC. For time

dependent crack growth process involving stress corrosion, sustained load crack growth or

creep crack growth, Kmax is the governing parameter [50,51]. However, due to the cyclic

nature of loading in fatigue, an additional parameter is needed, which describes the amplitude.

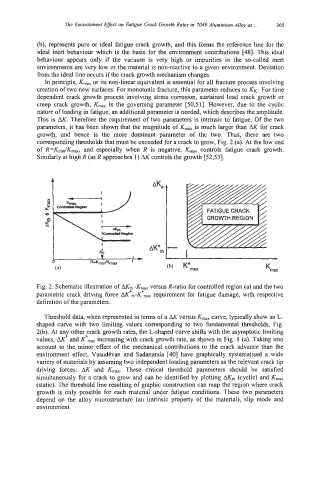

This is M. Therefore the requirement of two parameters is intrinsic to fatigue. Of the two

parameters, it has been shown that the magnitude of K- is much larger than AK for crack

growth, and hence is the more dominant parameter of the two. Thus, there are two

corresponding thresholds that must be exceeded for a crack to grow, Fig. 2 (a). At the low end

of R=Km,JKm, and especially when R is negative, Kmsx controls fatigue crack growth.

Similarly at high R (as R approaches 1) AK controls the growth [52,53].

Fig. 2. Schematic illustration of AKth -Kmx versus R-ratio for controlled region (a) and the two

parametric crack driving force hK*th-K*- requirement for fatigue damage, with respective

definition of the parameters.

Threshold data, when represented in terms of a AK versus Kmx curve, typically show an L-

shaped curve with two limiting values corresponding to two fundamental thresholds, Fig.

2(b). At any other crack growth rates, the L-shaped curve shifts with the asymptotic limiting

values, AK and K*- increasing with crack growth rate, as shown in Fig. 1 (a). Taking into

account to the minor effect of the mechanical contributions to the crack advance than the

environment effect, Vasudkvan and Sadananda [40] have graphically systematised a wide

variety of materials by assuming two independent loading parameters as the relevant crack tip

driving forces: AK and K-. These critical threshold parameters should be satisfied

simultaneously for a crack to grow and can be identified by plotting A&, (cyclic) and K,,

(static). The threshold line resulting of graphic construction can map the region where crack

growth is only possible for each material under fatigue conditions. These two parameters

depend on the alloy microstructure (an intrinsic property of the material), slip mode and

environment.