Page 87 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 87

Chapter | 3 Biomass Characteristics 65

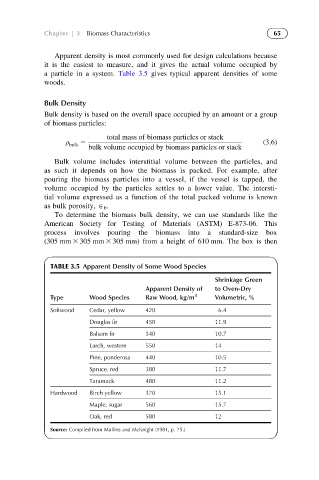

Apparent density is most commonly used for design calculations because

it is the easiest to measure, and it gives the actual volume occupied by

a particle in a system. Table 3.5 gives typical apparent densities of some

woods.

Bulk Density

Bulk density is based on the overall space occupied by an amount or a group

of biomass particles:

total mass of biomass particles or stack

ρ 5 (3.6)

bulk

bulk volume occupied by biomass particles or stack

Bulk volume includes interstitial volume between the particles, and

as such it depends on how the biomass is packed. For example, after

pouring the biomass particles into a vessel, if the vessel is tapped, the

volume occupied by the particles settles to a lower value. The intersti-

tial volume expressed as a function of the total packed volume is known

as bulk porosity, A b .

To determine the biomass bulk density, we can use standards like the

American Society for Testing of Materials (ASTM) E-873-06. This

process involves pouring the biomass into a standard-size box

(305 mm 3 305 mm 3 305 mm) from a height of 610 mm. The box is then

TABLE 3.5 Apparent Density of Some Wood Species

Shrinkage Green

Apparent Density of to Oven-Dry

Type Wood Species Raw Wood, kg/m 3 Volumetric, %

Softwood Cedar, yellow 420 6.4

Douglas fir 450 11.9

Balsam fir 340 10.7

Larch, western 550 14

Pine, ponderosa 440 10.5

Spruce, red 380 11.7

Taramack 480 11.2

Hardwood Birch yellow 370 15.1

Maple, sugar 560 15.7

Oak, red 580 12

Source: Compiled from Mullins and McKnight (1981, p. 75.)