Page 88 - Biomass Gasification, Pyrolysis And Torrefaction Practical Design and Theory

P. 88

66 Biomass Gasification, Pyrolysis and Torrefaction

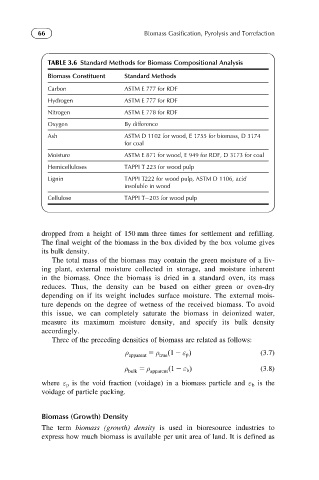

TABLE 3.6 Standard Methods for Biomass Compositional Analysis

Biomass Constituent Standard Methods

Carbon ASTM E 777 for RDF

Hydrogen ASTM E 777 for RDF

Nitrogen ASTM E 778 for RDF

Oxygen By difference

Ash ASTM D 1102 for wood, E 1755 for biomass, D 3174

for coal

Moisture ASTM E 871 for wood, E 949 for RDF, D 3173 for coal

Hemicelluloses TAPPI T 223 for wood pulp

Lignin TAPPI T222 for wood pulp, ASTM D 1106, acid

insoluble in wood

Cellulose TAPPI T 203 for wood pulp

dropped from a height of 150 mm three times for settlement and refilling.

The final weight of the biomass in the box divided by the box volume gives

its bulk density.

The total mass of the biomass may contain the green moisture of a liv-

ing plant, external moisture collected in storage, and moisture inherent

in the biomass. Once the biomass is dried in a standard oven, its mass

reduces. Thus, the density can be based on either green or oven-dry

depending on if its weight includes surface moisture. The external mois-

ture depends on the degree of wetness of the received biomass. To avoid

this issue, we can completely saturate the biomass in deionized water,

measure its maximum moisture density, and specify its bulk density

accordingly.

Three of the preceding densities of biomass are related as follows:

ρ 5 ρ (3.7)

apparent true ð1 2 ε p Þ

ρ bulk 5 ρ apparent ð1 2 ε b Þ (3.8)

where ε p is the void fraction (voidage) in a biomass particle and ε b is the

voidage of particle packing.

Biomass (Growth) Density

The term biomass (growth) density is used in bioresource industries to

express how much biomass is available per unit area of land. It is defined as