Page 338 - Biomimetics : Biologically Inspired Technologies

P. 338

Bar-Cohen : Biomimetics: Biologically Inspired Technologies DK3163_c012 Final Proof page 324 21.9.2005 11:55pm

324 Biomimetics: Biologically Inspired Technologies

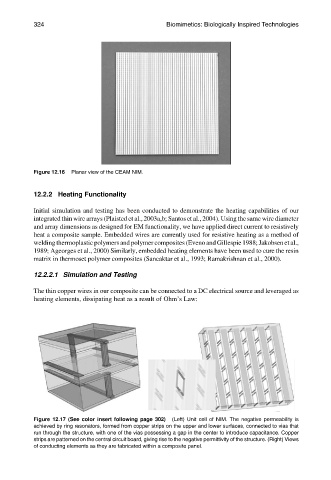

Figure 12.16 Planar view of the CEAM NIM.

12.2.2 Heating Functionality

Initial simulation and testing has been conducted to demonstrate the heating capabilities of our

integrated thin wire arrays (Plaisted et al., 2003a,b; Santos et al., 2004). Using the same wire diameter

and array dimensions as designed for EM functionality, we have applied direct current to resistively

heat a composite sample. Embedded wires are currently used for resistive heating as a method of

welding thermoplastic polymers and polymer composites (Eveno and Gillespie 1988; Jakobsen et al.,

1989; Ageorges et al., 2000) Similarly, embedded heating elements have been used to cure the resin

matrix in thermoset polymer composites (Sancaktar et al., 1993; Ramakrishnan et al., 2000).

12.2.2.1 Simulation and Testing

The thin copper wires in our composite can be connected to a DC electrical source and leveraged as

heating elements, dissipating heat as a result of Ohm’s Law:

Figure 12.17 (See color insert following page 302) (Left) Unit cell of NIM. The negative permeability is

achieved by ring resonators, formed from copper strips on the upper and lower surfaces, connected to vias that

run through the structure, with one of the vias possessing a gap in the center to introduce capacitance. Copper

strips are patterned on the central circuit board, giving rise to the negative permittivity of the structure. (Right) Views

of conducting elements as they are fabricated within a composite panel.