Page 300 - Biosystems Engineering

P. 300

Biodiesel and Ethanol in Engines 277

results in higher smoke because there is a lesser amount of oxygen

available. Hence, overloading the engine will result in a very black

smoke. It is observed that smoke level decreases with ethanol fumi-

gation. Fumigation of ethanol starts precombustion reactions before

and during a compression stroke, resulting in reduced chemical delay

because the intermediate products such as peroxides and aldehydes

react more rapidly with oxygen than with original hydrocarbons.

This shortening of the delay period curbs thermal cracking, which is

responsible for soot formation that results in a reduction of smoke. It

is observed that at an engine speed 800 rpm and at no load, the smoke

level is decreased by 91.66, 75, and 41.59 percent at ethanol fumiga-

tion rates of 1.06, 1.45, and 2.06 kg/h (45.00, 54.57, and 62.17 percent

diesel substitution), respectively, when compared to the smoke level

under diesel fuel operation. At a high load of 6.31 kW, the smoke

level is decreased by 68.18, 50.10, and 40.90 percent at ethanol fumi-

gation rates of 1.06, 1.45, and 2.06 kg/h, respectively, when compared

to the smoke level under diesel fuel operation.

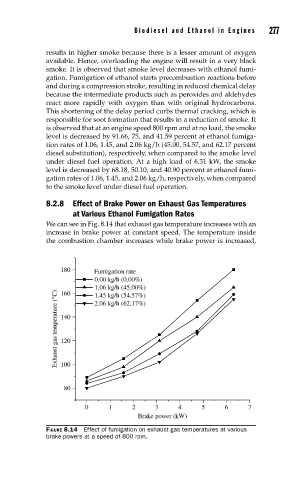

8.2.8 Effect of Brake Power on Exhaust Gas Temperatures

at Various Ethanol Fumigation Rates

We can see in Fig. 8.14 that exhaust gas temperature increases with an

increase in brake power at constant speed. The temperature inside

the combustion chamber increases while brake power is increased,

180 Fumigation rate

0.00 kg/h (0.00%)

1.06 kg/h (45.00%)

Exhaust gas temperature (°C) 140

160

1.45 kg/h (54.57%)

2.06 kg/h (62.17%)

120

100

80

0 1 2 3 4 5 6 7

Brake power (kW)

FIGURE 8.14 Effect of fumigation on exhaust gas temperatures at various

brake powers at a speed of 800 rpm.