Page 295 - Biosystems Engineering

P. 295

272 Cha pte r Ei g h t

stroke, resulting in a reduction in brake thermal efficiency. At an

engine speed of 800 rpm and at a 1.58-kW load, brake thermal effi-

ciency is decreased by 1.11, 1.33, and 2.30 percent at ethanol fumiga-

tion rates of 1.06, 1.45, and 2.06 kg/h (45, 54.57, and 62.17 percent

diesel substitution), respectively, when compared to the brake ther-

mal efficiency under diesel operation. At ethanol fumigation rate of

1.06 kg/h (45 percent diesel substitution) and at low load (1.58 kW)

the brake thermal efficiency is reduced by 1.11, 2.49, 0.96, and

1.53 percent at engine speed of 800, 900, 1000, and 1100 rpm, respec-

tively, when compared to the efficiency under diesel fuel operation.

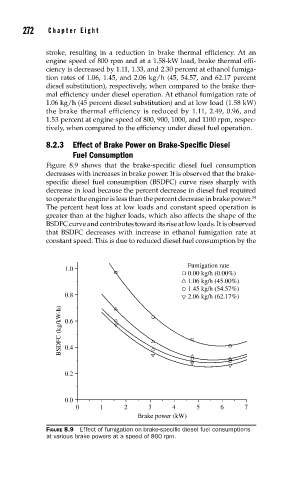

8.2.3 Effect of Brake Power on Brake-Specific Diesel

Fuel Consumption

Figure 8.9 shows that the brake-specific diesel fuel consumption

decreases with increases in brake power. It is observed that the brake-

specific diesel fuel consumption (BSDFC) curve rises sharply with

decrease in load because the percent decrease in diesel fuel required

to operate the engine is less than the percent decrease in brake power. 34

The percent heat loss at low loads and constant speed operation is

greater than at the higher loads, which also affects the shape of the

BSDFC curve and contributes toward its rise at low loads. It is observed

that BSDFC decreases with increase in ethanol fumigation rate at

constant speed. This is due to reduced diesel fuel consumption by the

Fumigation rate

1.0

0.00 kg/h (0.00%)

1.06 kg/h (45.00%)

1.45 kg/h (54.57%)

0.8 2.06 kg/h (62.17%)

BSDFC (kg/kW-h) 0.6

0.4

0.2

0.0

0 1 2 3 4 5 6 7

Brake power (kW)

FIGURE 8.9 Effect of fumigation on brake-specifi c diesel fuel consumptions

at various brake powers at a speed of 800 rpm.