Page 316 - Boiler_Operators_Handbook,_Second_Edition

P. 316

Plants and Equipment 301

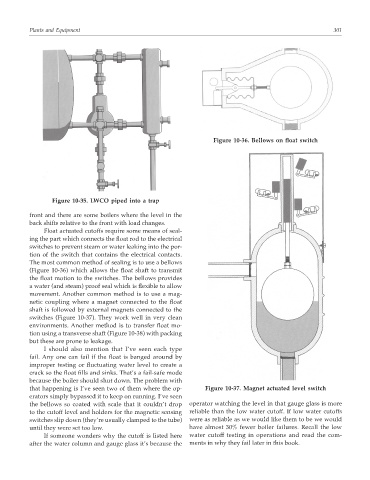

Figure 10-36. Bellows on float switch

Figure 10-35. LWCO piped into a trap

front and there are some boilers where the level in the

back shifts relative to the front with load changes.

Float actuated cutoffs require some means of seal-

ing the part which connects the float rod to the electrical

switches to prevent steam or water leaking into the por-

tion of the switch that contains the electrical contacts.

The most common method of sealing is to use a bellows

(Figure 10-36) which allows the float shaft to transmit

the float motion to the switches. The bellows provides

a water (and steam) proof seal which is flexible to allow

movement. Another common method is to use a mag-

netic coupling where a magnet connected to the float

shaft is followed by external magnets connected to the

switches (Figure 10-37). They work well in very clean

environments. Another method is to transfer float mo-

tion using a transverse shaft (Figure 10-38) with packing

but these are prone to leakage.

I should also mention that I’ve seen each type

fail. Any one can fail if the float is banged around by

improper testing or fluctuating water level to create a

crack so the float fills and sinks. That’s a fail-safe mode

because the boiler should shut down. The problem with

that happening is I’ve seen two of them where the op- Figure 10-37. Magnet actuated level switch

erators simply bypassed it to keep on running. I’ve seen

the bellows so coated with scale that it couldn’t drop operator watching the level in that gauge glass is more

to the cutoff level and holders for the magnetic sensing reliable than the low water cutoff. If low water cutoffs

switches slip down (they’re usually clamped to the tube) were as reliable as we would like them to be we would

until they were set too low. have almost 30% fewer boiler failures. Recall the low

If someone wonders why the cutoff is listed here water cutoff testing in operations and read the com-

after the water column and gauge glass it’s because the ments in why they fail later in this book.