Page 181 - Boiler plant and distribution system optimization manual

P. 181

166 Boiler Plant and Distribution System Optimization Manual

rates steam from condensate and the low pressure

flash steam is piped off to some useful purpose.

Only as a last resort should flash steam be vented

to the atmosphere and lost.

Advantages/Disadvantages

New coils or heat exchangers may be re-

quired to utilize the flash steam for heating and

other uses. Flash steam possibilities are becoming

recognized.

21. USE HOT CONDENSATE TO KEEP

STORAGE TANKS WARM (LOCAL USE)

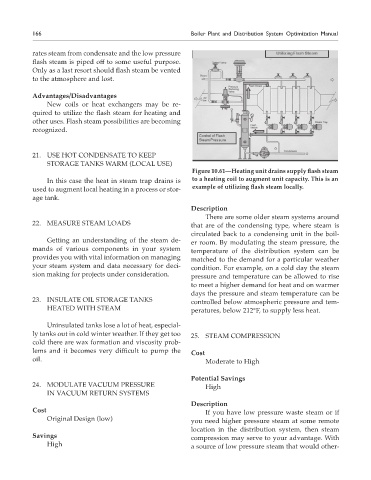

Figure 10.61—Heating unit drains supply flash steam

In this case the heat in steam trap drains is to a heating coil to augment unit capacity. This is an

example of utilizing flash steam locally.

used to augment local heating in a process or stor-

age tank.

Description

There are some older steam systems around

22. MEASURE STEAM LOADS that are of the condensing type, where steam is

circulated back to a condensing unit in the boil-

Getting an understanding of the steam de- er room. By modulating the steam pressure, the

mands of various components in your system temperature of the distribution system can be

provides you with vital information on managing matched to the demand for a particular weather

your steam system and data necessary for deci- condition. For example, on a cold day the steam

sion making for projects under consideration. pressure and temperature can be allowed to rise

to meet a higher demand for heat and on warmer

days the pressure and steam temperature can be

23. INSULATE OIL STORAGE TANKS controlled below atmospheric pressure and tem-

HEATED WITH STEAM peratures, below 212°F, to supply less heat.

Uninsulated tanks lose a lot of heat, especial-

ly tanks out in cold winter weather. If they get too 25. STEAM COMPRESSION

cold there are wax formation and viscosity prob-

lems and it becomes very difficult to pump the Cost

oil. Moderate to High

Potential Savings

24. MODULATE VACUUM PRESSURE High

IN VACUUM RETURN SYSTEMS

Description

Cost If you have low pressure waste steam or if

Original Design (low) you need higher pressure steam at some remote

location in the distribution system, then steam

Savings compression may serve to your advantage. With

High a source of low pressure steam that would other-