Page 182 - Boiler plant and distribution system optimization manual

P. 182

Over 100 Ways to Improve Efficiency 167

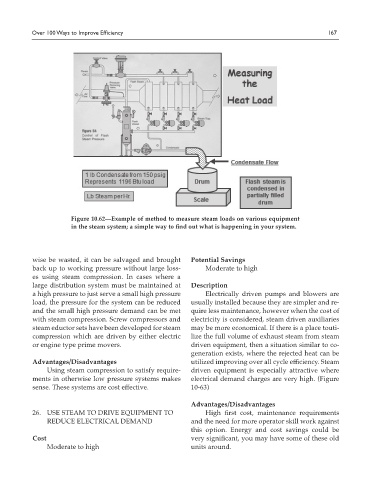

Figure 10.62—Example of method to measure steam loads on various equipment

in the steam system; a simple way to find out what is happening in your system.

wise be wasted, it can be salvaged and brought Potential Savings

back up to working pressure without large loss- Moderate to high

es using steam compression. In cases where a

large distribution system must be maintained at Description

a high pressure to just serve a small high pressure Electrically driven pumps and blowers are

load, the pressure for the system can be reduced usually installed because they are simpler and re-

and the small high pressure demand can be met quire less maintenance, however when the cost of

with steam compression. Screw compressors and electricity is considered, steam driven auxiliaries

steam eductor sets have been developed for steam may be more economical. If there is a place touti-

compression which are driven by either electric lize the full volume of exhaust steam from steam

or engine type prime movers. driven equipment, then a situation similar to co-

generation exists, where the rejected heat can be

Advantages/Disadvantages utilized improving over all cycle efficiency. Steam

Using steam compression to satisfy require- driven equipment is especially attractive where

ments in otherwise low pressure systems makes electrical demand charges are very high. (Figure

sense. These systems are cost effective. 10-63)

Advantages/Disadvantages

26. USE STEAM TO DRIVE EQUIPMENT TO High first cost, maintenance requirements

REDUCE ELECTRICAL DEMAND and the need for more operator skill work against

this option. Energy and cost savings could be

Cost very significant, you may have some of these old

Moderate to high units around.