Page 187 - Boiler plant and distribution system optimization manual

P. 187

172 Boiler Plant and Distribution System Optimization Manual

nus inlet combustion air temperature). There are 5. HEAT RECOVERY USING

several types of air heaters: The tubular type air PLATE ExCHANGERS

heater (Figure 10.69) circulates cooler combustion

air around hot tubes which are heated by exhaust Cost

gases. Several novel but effective designs have Moderate

emerged for this type of heater; glass tubes have

been used for applications where corrosion is a Potential Savings

problem. Also, Teflon coated tubes are used if you Moderate to High

wish to bring flue gas temperatures below the

dew point. Heat pipes are also being introduced Description

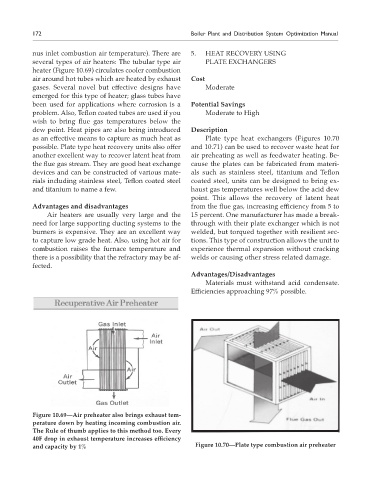

as an effective means to capture as much heat as Plate type heat exchangers (Figures 10.70

possible. Plate type heat recovery units also offer and 10.71) can be used to recover waste heat for

another excellent way to recover latent heat from air preheating as well as feedwater heating. Be-

the flue gas stream. They are good heat exchange cause the plates can be fabricated from materi-

devices and can be constructed of various mate- als such as stainless steel, titanium and Teflon

rials including stainless steel, Teflon coated steel coated steel, units can be designed to bring ex-

and titanium to name a few. haust gas temperatures well below the acid dew

point. This allows the recovery of latent heat

Advantages and disadvantages from the flue gas, increasing efficiency from 5 to

Air heaters are usually very large and the 15 percent. One manufacturer has made a break-

need for large supporting ducting systems to the through with their plate exchanger which is not

burners is expensive. They are an excellent way welded, but torqued together with resilient sec-

to capture low grade heat. Also, using hot air for tions. This type of construction allows the unit to

combustion raises the furnace temperature and experience thermal expansion without cracking

there is a possibility that the refractory may be af- welds or causing other stress related damage.

fected.

Advantages/Disadvantages

Materials must withstand acid condensate.

Efficiencies approaching 97% possible.

Figure 10.69—Air preheater also brings exhaust tem-

perature down by heating incoming combustion air.

The Rule of thumb applies to this method too. Every

40F drop in exhaust temperature increases efficiency

and capacity by 1% Figure 10.70—Plate type combustion air preheater